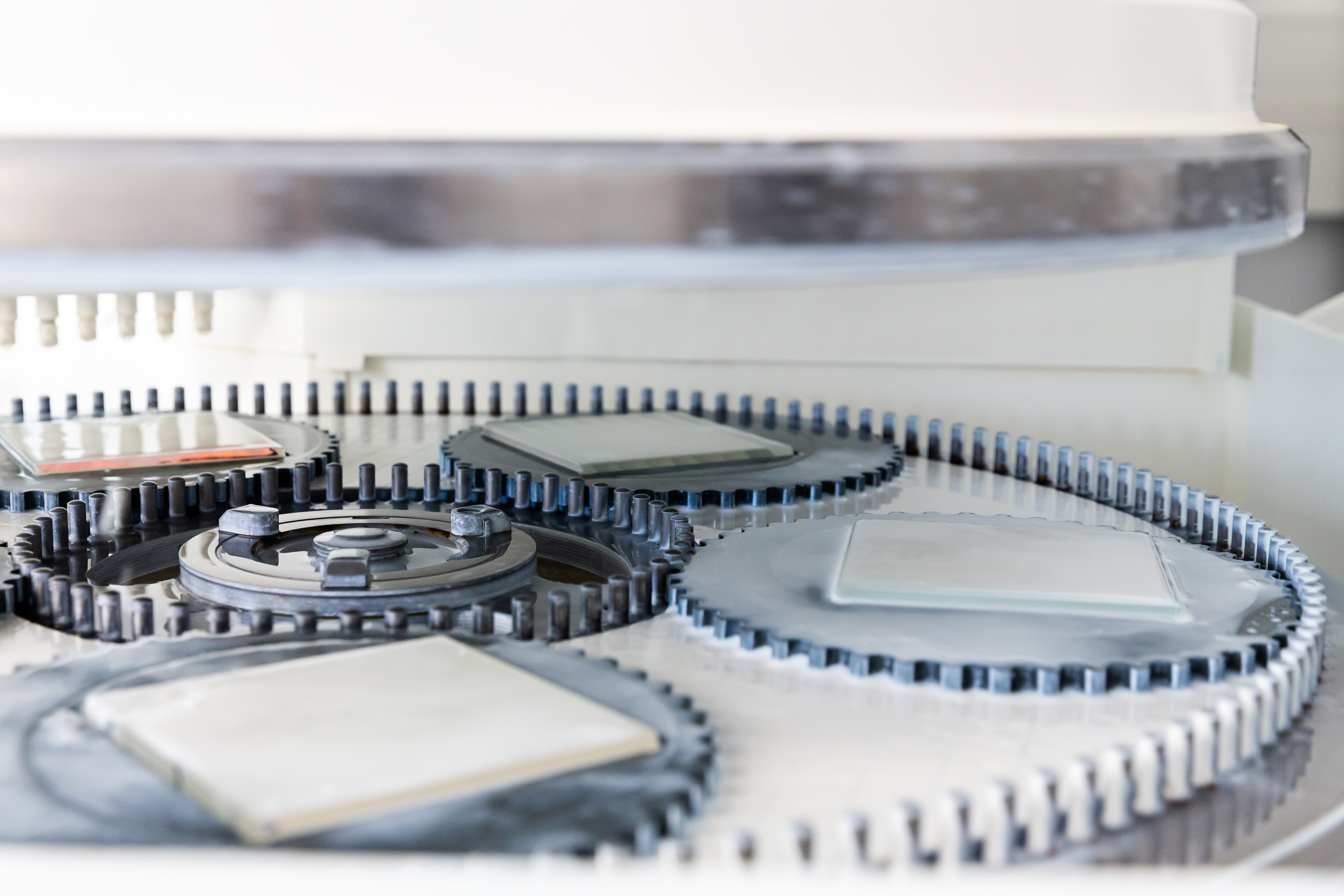

Diamond Tools

for plano and plano parallel processing, spherical optics, micro and macro optics as well as aspherical and cylindrical geometries

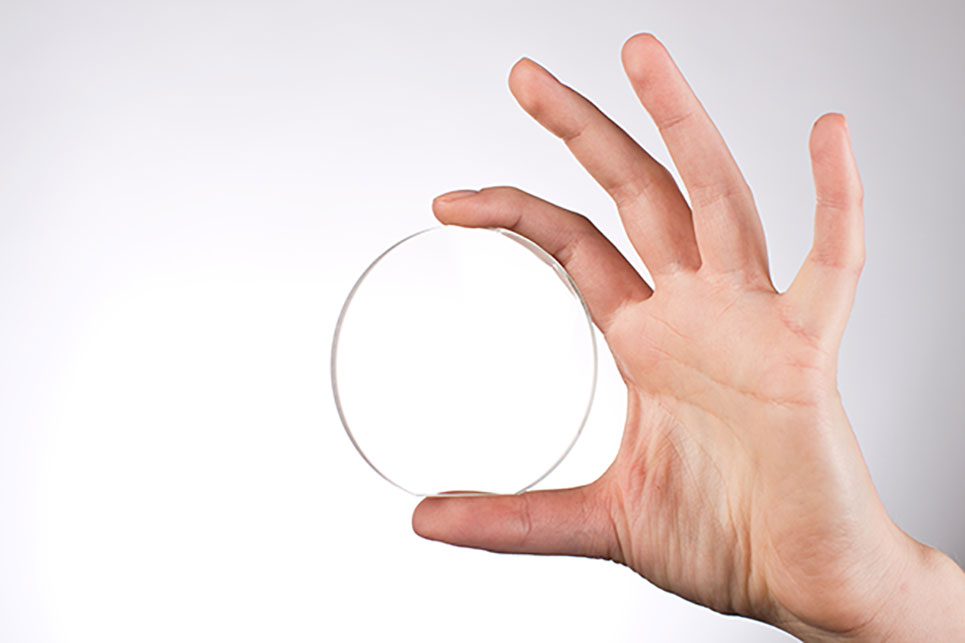

Plano Optics

such as laser optical windows, mirrors and other geometries out of optical glass, fused silica, CaF2, sapphire, YAG, glass ceramic and many more materials

Contract Work & Services

such as grinding, lapping, polishing, chamfering and brushing, laser cutting and engraving, coating, metallization, wafer reclaim as well as measuring services

Benefits of dopa Tools & Technologies

Ultra-homogeneous surfaces

dopa tools create ultra-homogeneous surfaces with minimal subsurface damage – even with high removal rates.

Reduced polishing times

Thanks to the minimal subsurface damage polishing times are reduced significantly. This enhances product quality and quantity as well as process stability.

Sharp edges free from chippings

dopa tools are characterized by the sharp and chip-free edges they produce. Consequently, they are particularly suited for the manufacturing of prisms, sealings, beam splitters or equivalent components.

High dimensional accuracy

dopa tools are used for 24/7 mass production of components due to their reproduceable dimensional accuracy.

Optically measurable surfaces

The ultrafine surfaces created by dopa tools are already optically and interferometrically measurable. Therefore, the produced parts can be much more precise than usual.

Very clean process

The replacements of abrasive grinding processes with dopa grinding tools greatly improves the cleanliness and reduces cleaning efforts of the components. Grain residues are avoided, which cuts down time for cleaning and increases the yield significantly.