Realization of your process and product ideas

We offer our customers the development of products and processes for planar processing of optical glass, crystals, ceramics, and many other special materials. Our service portfolio entails feasibility studies, prototype and small badge production as well as support in setting up mass production of precision components.

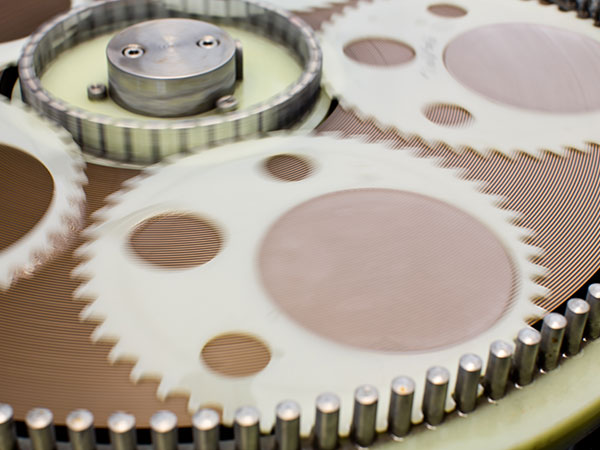

Besides the classic processes such as grinding, lapping and polishing, diamond polishing or CMP, we also cover sub processes and add-ons like chamfering, laser engraving/cutting, brushing, cleaning, or optical coatings.

Our portfolio

As a specialist for diamond tools, we can assist you in the selection of suitable processing tools from our full range of several thousand tool assortments. Even for very delicate materials we can rapidly work out a tool solution as we have all production steps located inhouse. This also applies to all essential consumables and accessories, which are produced here at our premises, too.

Our entire portfolio of machinery and measurement equipment is available to you. This allows us to run machining trails under real production conditions, which facilitates a fast and efficient ramp-up.

Please discuss your needs with one of our contacts for product & process development.

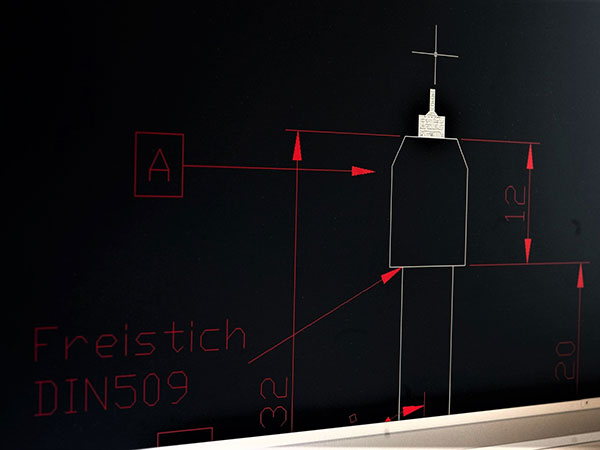

Pre-machining

Grinding, fine grinding, lapping, flat honing, chamfering (edge rounding and polishing), brushing

Fine machining and finish

Polishing, diamond polishing, chemical-mechanical polishing, fine cleaning

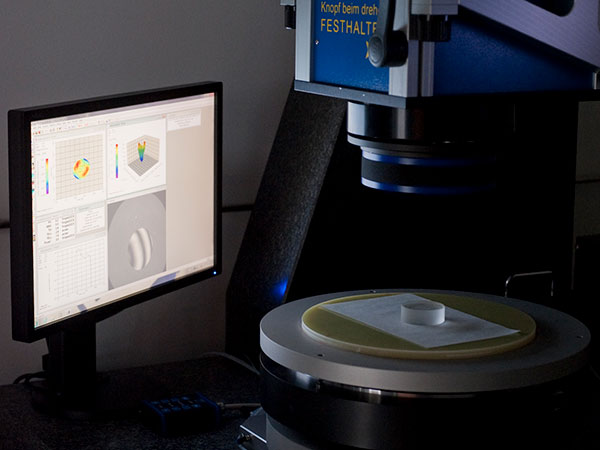

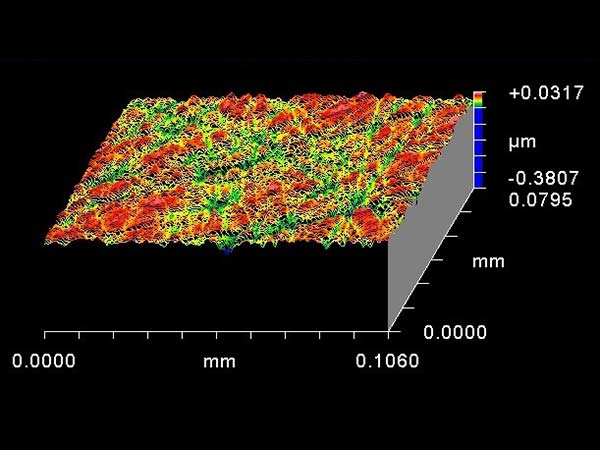

Metrology

Light microscope, optical test light measurement station, tactile surface roughness measurement, tactile precision thickness measurement, grazing incidence interferometer for parts of up to 200 mm, Fizeau interferometer for parts of up to 1500 mm, white light interferometer for measurements with Ångstrom accuracy

Grafting and add-ons

Laser engraving, coating, drilling, separating and cutting

Realization of your ideas

Depending on your goals, we carry out feasibility studies, manufacture prototypes and identify the process and tools parameters to reach the required specifications of your components under real production conditions. When it comes to transferring the results, you can choose from one of the following options:

- Supply: As a supplier, we provide you with tools and consumables for processing on your own machinery. Of course, blanket and call orders, or for several products even a 24h delivery service, can be arranged.

- Contract work: The new process can be carried out by dopa as contract work. This is particularly suitable for a quick ramp-up or to cover or increase capacity. Our plano optics manufacturing line is ISO9001 certified and includes (upon agreement) extended documentation and certified conformity.

- Turnkey solution: dopa can implement turnkey solutions at your production site. This includes the installation and initiation of machinery and processes as well as intensive staff training.

Many renowned global companies already use our services to optimize existing process lines or to set up new production lines.

Discuss your goals with us. We develop your efficiency!

Benefits of the dopa process development

- Targeted realization of your process- and/or product idea

- A motivated research & development team with longstanding practical experience in the optics, metal and semiconductor industry

- Access to the complete range of tools, consumables, machinery and measurement equipment of a modern plano optics shop

- Development under production conditions facilitate a fast ramp-up to the mass production

- One-stop-shop for the identification and realization of turnkey process solutions

Martin Patraschkov

Head of Tools & Process Development

+49 (0)30 5858428 61

martin@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.