No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

We have developed a special hybrid bond for radius milling tools. This composition combines the benefits of metal bonded tools (cutting performance, endurance and good cooling properties) and resin bonded tooling (homogeneous scratch-free surfaces, very low sub surface damage, optically measurable after grinding, reduced polishing times).

We can provide you with radius milling tools in different grit sizes and dimensions. You can choose from

standardized hydraulic taper shanks or get your specific tool interfaces.

Please contact us.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

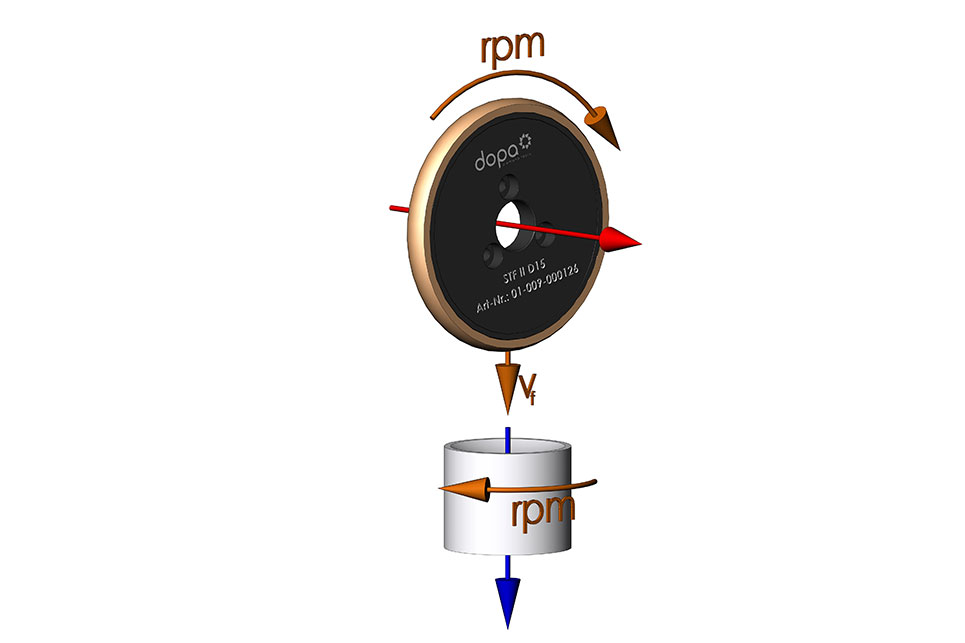

Aspheres can be generated in various ways. In precision optics, it is common to first create a sphere in best-fit radius before processing them with grinding wheels or ball tools.

Aspheres can be generated in various ways. In precision optics, it is common to first create a sphere in best-fit radius before processing them with grinding wheels or ball tools.

We have developed a special hybrid bond for this application. It’s composition combines the benefits of metal bonded tools (cutting performance, endurance and good cooling properties) and resin bonded tooling (homogeneous scratch-free surfaces, very low sub surface damage, optically measurable after grinding, reduced polishing times).

Our tools are characterized by very good cutting properties with extremely low sub surface damage. Consequently, it is possible to already measure such complex shapes interferometrically after the grinding process. This means that corrections can take place early on, which reduces polishing times and keeps shape errors as low as possible.

By using our tools, you are technologically on the cutting-edge and benefit from continued development.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.