No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Machinery & Plant Engineering »

The combination of sedimentation and 2-phase ultra-fine filtration enables a 3-phase filtration process. dopa coolant filtration systems are further equipped with:

Various further options are available upon request. We build coolant filtration systems according to your needs. Please contact us to discuss your specifications.

Please see the data sheet – dopa coolant filtration systems to access the detailed machine description. (PDF).

Internal Sales for Tools, Machines & Consumables

+49 (0)30 585 84 28 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

We develop and produce grinding wheels for all machine types and sizes – for single- as well as double-sided machines. Depending on your very needs, we will create the best grinding wheel to produce your components.

We gladly consult you:

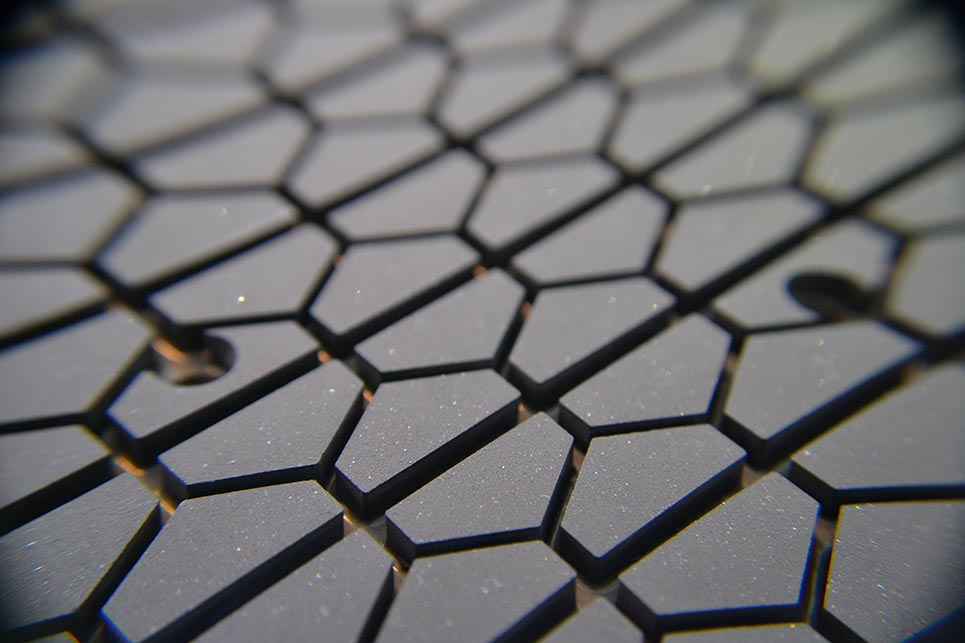

Segmented grinding wheels are used for grinding very thin parts or a high density of components. The segmentation of the grinding wheel is above all to avoid tilting of the processed parts and to improve the edge sharpness.

The gap between the segments can be chosen flexibly and is usually determined by the size of the smallest components that need to be processed.

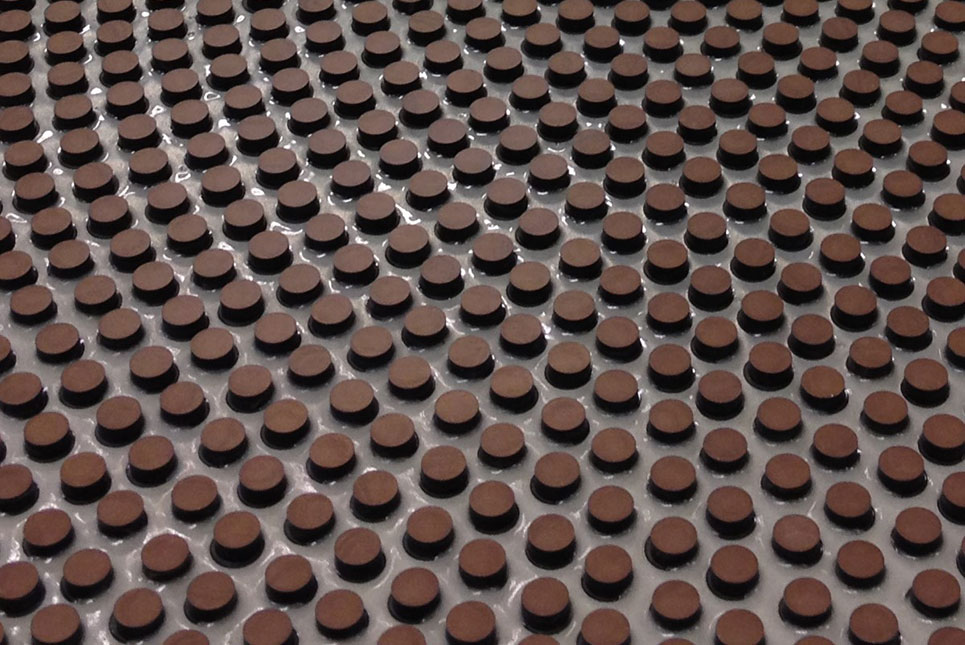

Pelleted grinding wheels are used where high removal rates combined with relatively low pressure are required.

These grinding wheels ensure a good removal of chipping and therefore avoid that clogging of the tools.

Grit size and pattern are completely flexible. We produce grinding wheels customized exactly to your production needs.

Fully covered grinding wheels are typically used when many small items need to be processed at the same time. In the micro optics or watches industry, for example, several hundred components are ground simultaneously.

The full coverage ensures that all components are processed evenly on the grinding wheel. It avoids clipping or tilting of parts during the transition from one grinding segment to the next.

Subsequently, the edge quality of the components is improved and the risk of damage minimized, while the surface finish is significantly increased.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

We produce polishing wheels for single- and double-sided machines as well as CNC tools, which can be customized to your machine and application requirements.

Our polishing wheels perform at polishing a number of different materials. Here is a collection of some of them:

All our tools are ground in with high precision and customized according to your needs.

Please contact us to discuss your specification.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

For all our grinding tools as well as our polishing pads and tools, we supply customized dressing and conditioning tools.

Please contact us for your non-committal consultation.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Diamond Tools »

Whether you are looking to process angular or round components, we have the right tooling and solution for you. We offer grinding and polishing solutions for angular, round and free-form workpieces. We produce radius and plano grinding wheels in almost all sizes and grits and of course customized tooling. We cover solutions for manual chamfering as well as tools for CNC machines.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.