No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Consumables »

We produce polishing slurries for the surface finishing of various materials. By using these slurries in your polishing process, you will achieve superior flatness, material removal rate and surface quality.

These slurries with evenly dispersed grit are very stable and offer a long-time use.

Colloidal silica polishing slurry for polishing of materials such as sapphire, silicon, YAG and calcium fluoride.

Particle size: 7 – 10 nm

Colloidal silica polishing slurry for polishing materials such as sapphire, silicon, YAG and calcium fluoride.

Particle size: XC-35: 50 nm

Particle size: XC-40: 90 nm

Polishing slurry made of rare earths (Ce) for the surface finishing of glass.

We also produce other slurries for materials such as sapphire, silicon carbide and other ultra-hard carbides and nitrides. We would be pleased to determine the right solution for your needs.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

ASM for Tools & Machines

VP of Business Development North America

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Machinery & Plant Engineering »

We build efficient systems for high precision supply and temperature control of polishing slurries and suspensions. These can be utilized in the area of high precision machining and are suitable for polishing machines or other machines that require precision temperature-controlled fluid feed or applications where you want to recycle fluids.

dopa polishing slurry systems have electronic temperature control, quick couplings on all electrical connections and media lines as well as different chilling options:

Various further options are available upon request. We build polishing slurry systems according to your needs. Please contact us to discuss your specifications.

Please see the data sheet – dopa polishing slurry systems to access the detailed machine description (PDF).

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

ASM for Tools & Machines

VP of Business Development North America

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

We also offer double-sided grinding, lapping and polishing machines. Working 30 years in the development and production of diamond tooling as well as producing precision optics and semiconductor substrates gives us the background to understand your requirements and transfer them into the needed machine.

Please contact us to discuss your specifications.

Automatic pressure control

Online tracking of temperatures, torques, and pressures

Robust machine with a very small footprint

Temperature- and flow-controlled media supply

Easy cleaning and maintenance of the entire machine

Automatic disk cleaning unit

User-friendly dopa software with high flexibility for adapting to specific requirements

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

ASM for Tools & Machines

VP of Business Development North America

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Home » Products » Machinery & Plant Engineering »

We build efficient coolant filtration systems for processing, filtering, pumping and temperature controlling coolants and cutting fluids. Our coolant filtration systems can be utilized in the machining of glass, ceramics and metals. They are suitable for grinding, generating, sawing and milling machines and serve as a substitute for centrifuges. The integrated water-water-chiller can be connected with the central cooling system or external cooling unit.

The combination of sedimentation and 2-phase ultra-fine filtration enables a 3-phase filtration process. dopa coolant filtration systems are further equipped with:

Various further options are available upon request. We build coolant filtration systems according to your needs. Please contact us to discuss your specifications.

Please see the data sheet – dopa coolant filtration systems to access the detailed machine description. (PDF).

Contact us with your requirements for your customized quote! We are always happy to assist you with our expertise in customization.

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

ASM for Tools & Machines

VP of Business Development North America

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

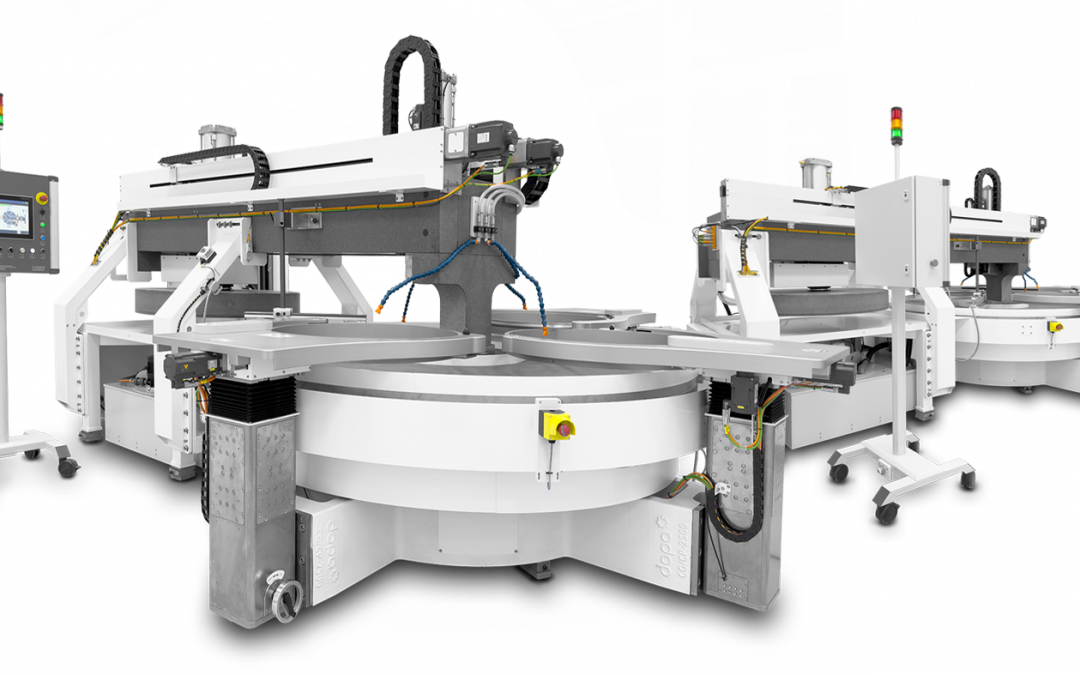

Home » Products » Machines » Continuous grinding and polishing machines »

Abb.: CP2500

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

ASM for Tools & Machines

VP of Business Development North America

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information