Home » Products » Machines » Single-sided Machines »

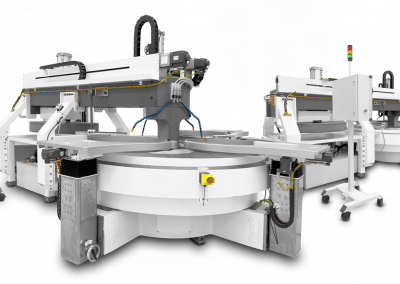

SGM500

Our state-of-the-art single-sided machines are specially developed and optimised for precision grinding, lapping and polishing applications, based on decades of application experience. They offer easy and comfortable operation as well as high efficiency and maintenance-friendly. Each machine can be tailor-made according to your individual needs and is also available as a turnkey solution, incl. process and all side equipment.

Technical Data

- Massive and stiff machine body for highest accuracy and no bending

- Compact design

- Spindle and eccentric arm out of stainless steel

- Fully servo controlled motors

- Freely programmable movements of the eccentric arm

- Digitized and visualized parameters

- Variable parameters among different process steps

- Storage of up to 60 recipes

- Automatic and manual mode

- Coolant supply through the spindle & from the outside

- Automatic lubrication system

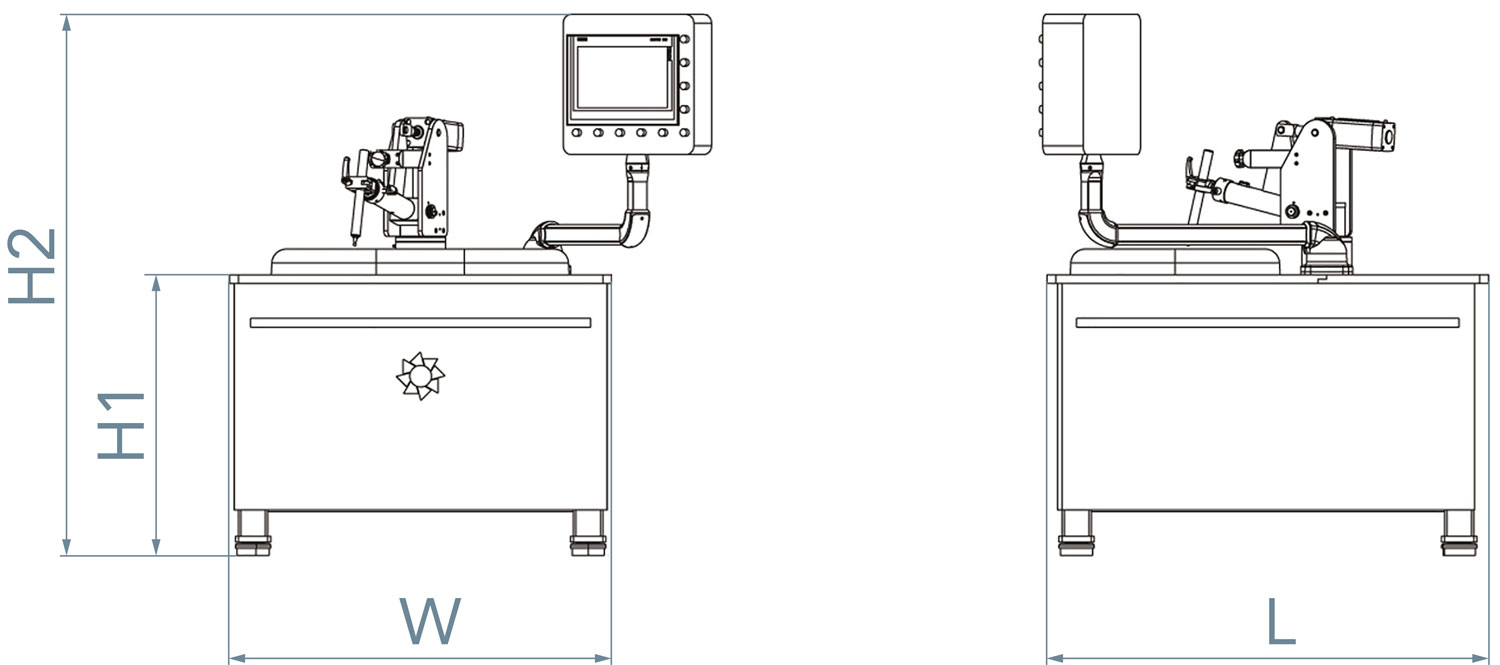

| SGM500NC | Technical data |

|---|---|

| Max. tool diameter | 700mm |

| Max. spindle speed | 200 RPM |

| Down force | 1-180 RPM |

| Basin size | 700x1.000 |

| Eccentric are | +/- 30° |

| Thread on tool spindle | M39 |

| Electric connection | 400V-3Ph-50Hz-16A |

| Weight | ~1.000kg |

| Dimension L x W x H1/H2 | 150 x 130 x 96/185 |

PDF Download

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please do not hesitate to contact us. We would gladly support you with our expertise and customize the machines to your needs.