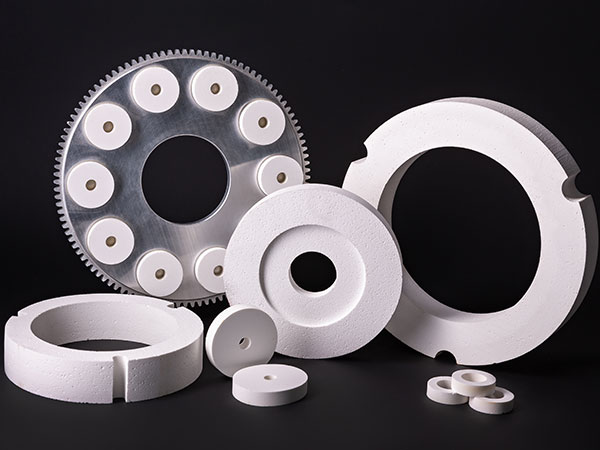

Polishing Pads

Home » Products » Consumables »

Polishing Pads

Polishing Pads

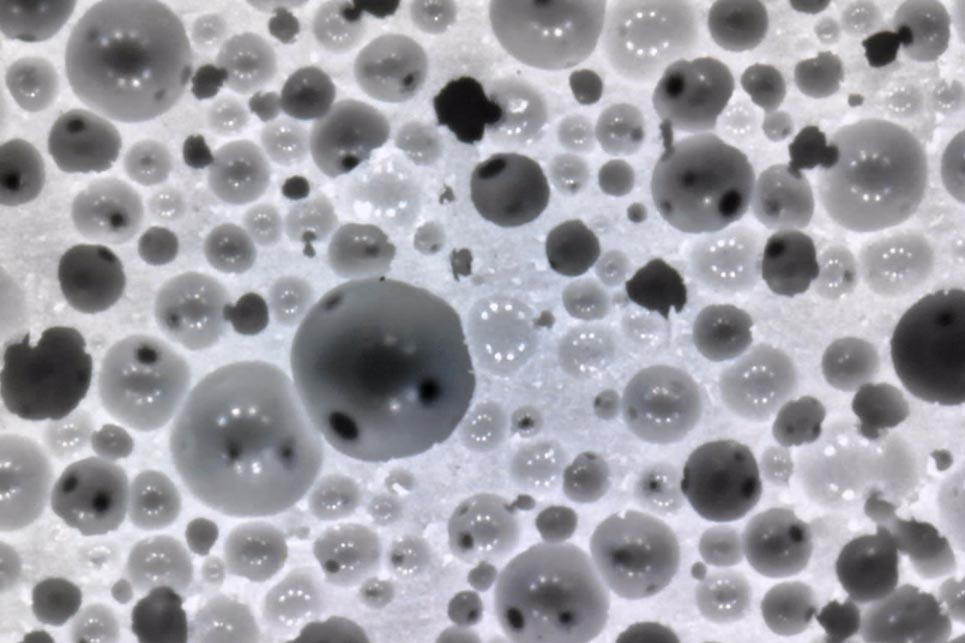

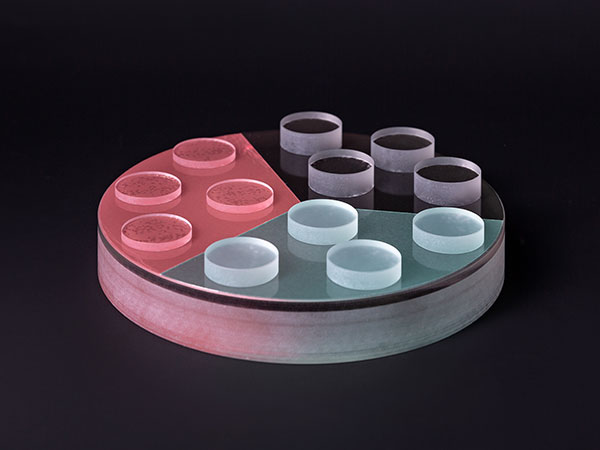

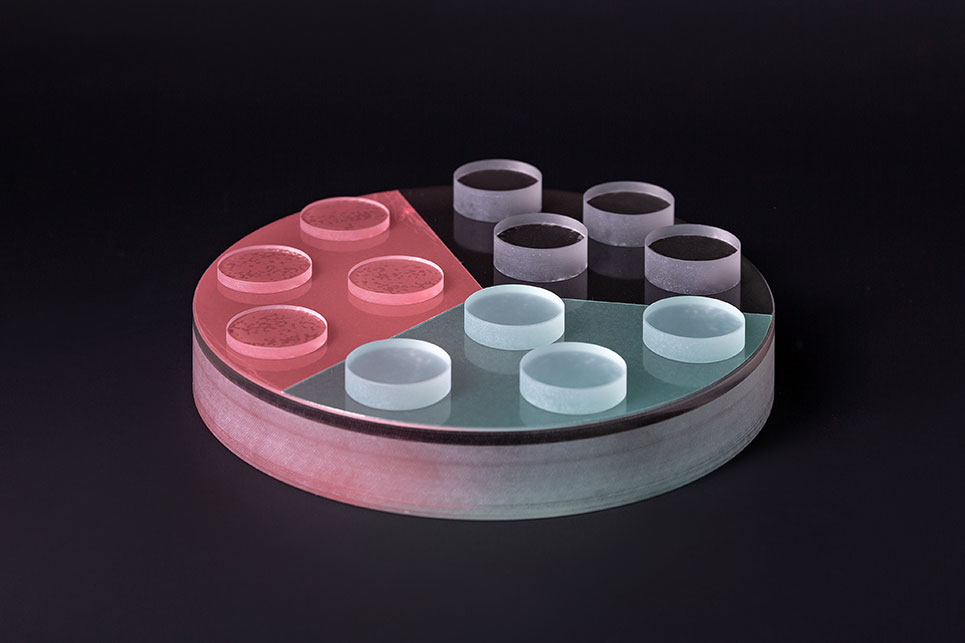

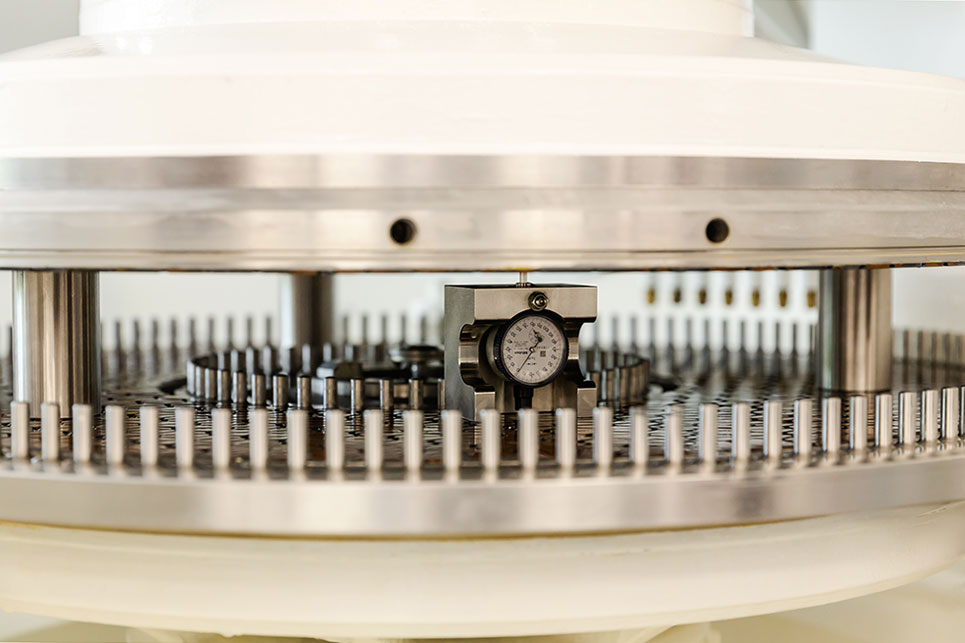

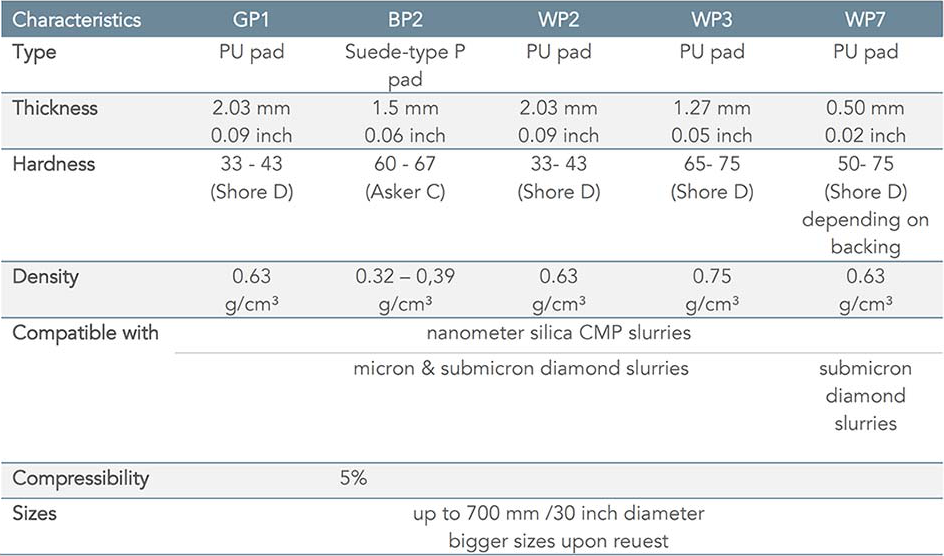

With dopa polishing pads you will achieve superior flatness, material removal rate (MRR) and surface

quality on materials like glass, sapphire, silicon carbide and other ultra-hard carbides and nitrides.

The dopa GP-1 works with Silica CMP slurries as well as with diamond slurries. You will achieve the best process results when using the pad in combination with dopa polishing slurries.

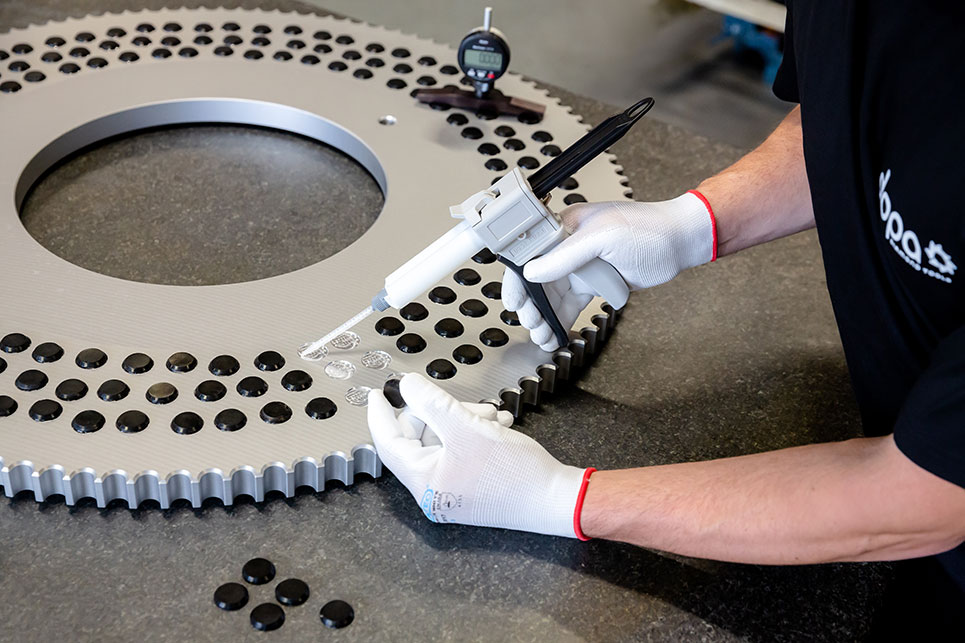

Customized grooving and slurry holes available upon request.

Benefits of polishing pads

- High material removal rate (MRR)

- Excellent (with GP1, WP2-7) /good (with BP2) part flatness and TTV

- Improves the surface finish and the subsurface damage of your parts

- Minimizes edge-rounding and orange-peel

- Keeps the removal rate stable giving you better process control

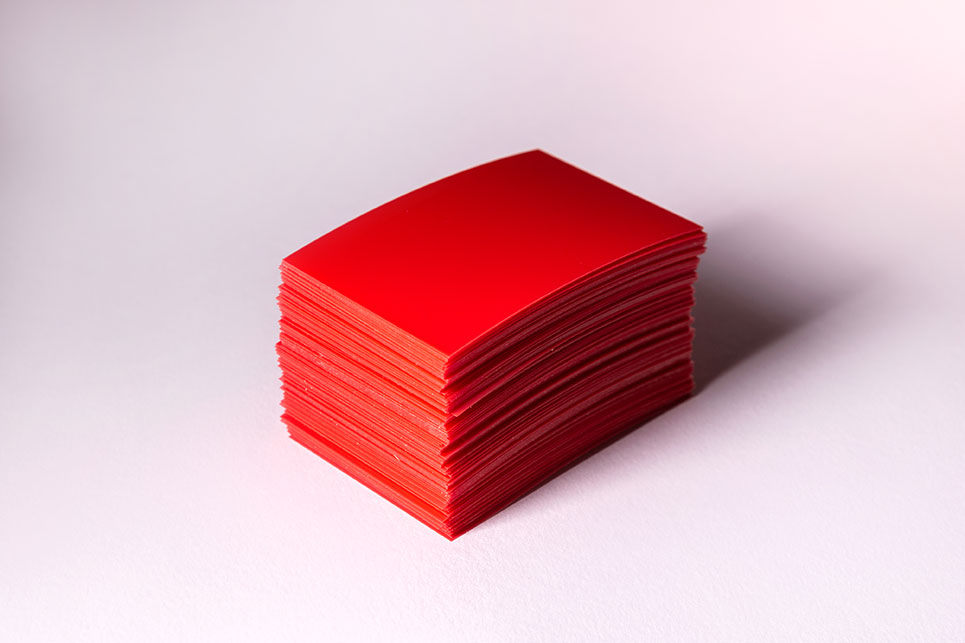

- Very durable pad with long lifetime

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.