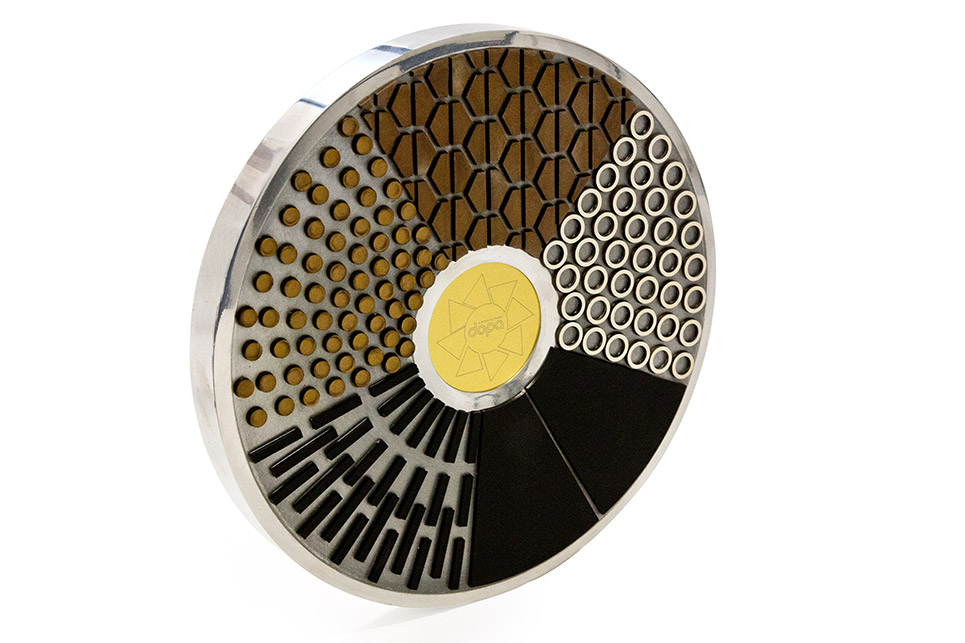

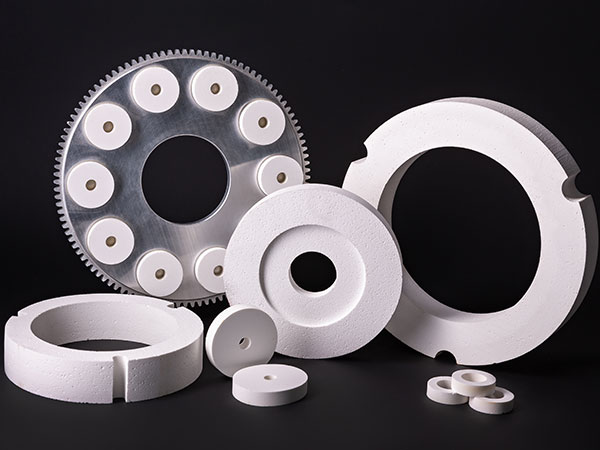

Dressing & Conditioning Tools

Home » Products » Consumables »

Dressing & Conditioning Tools

Dressing & Conditioning Tools

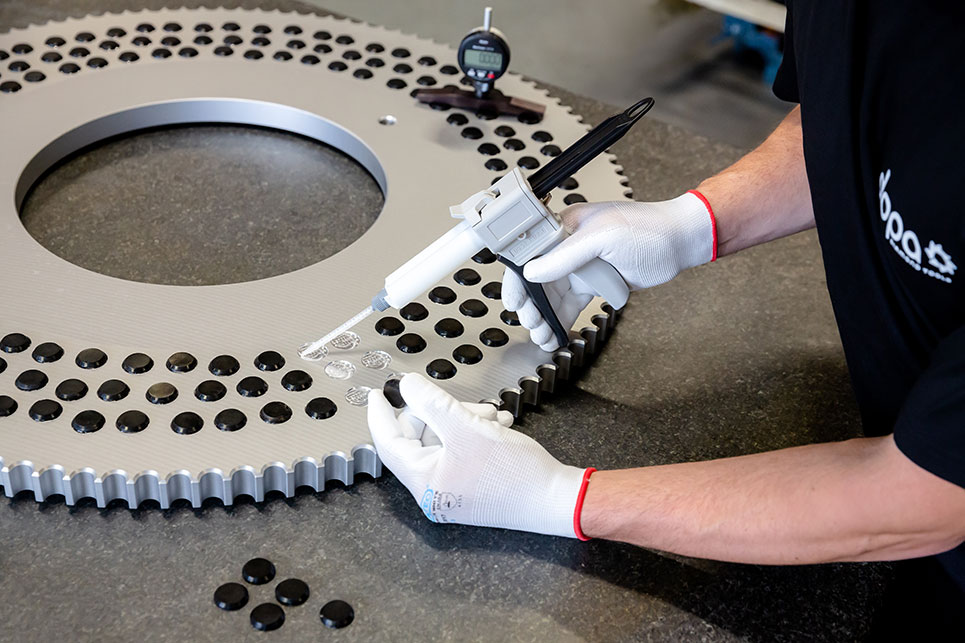

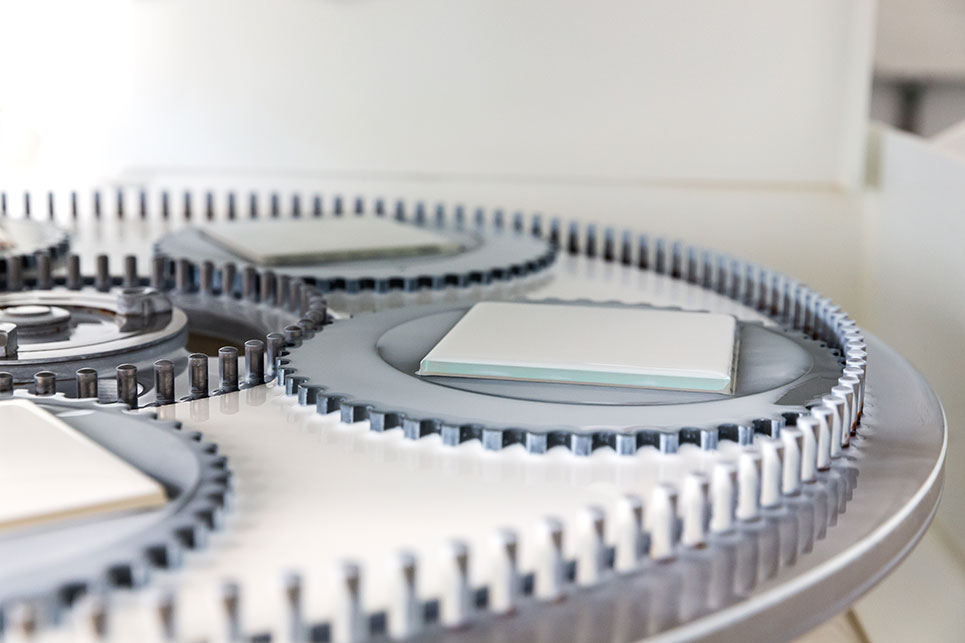

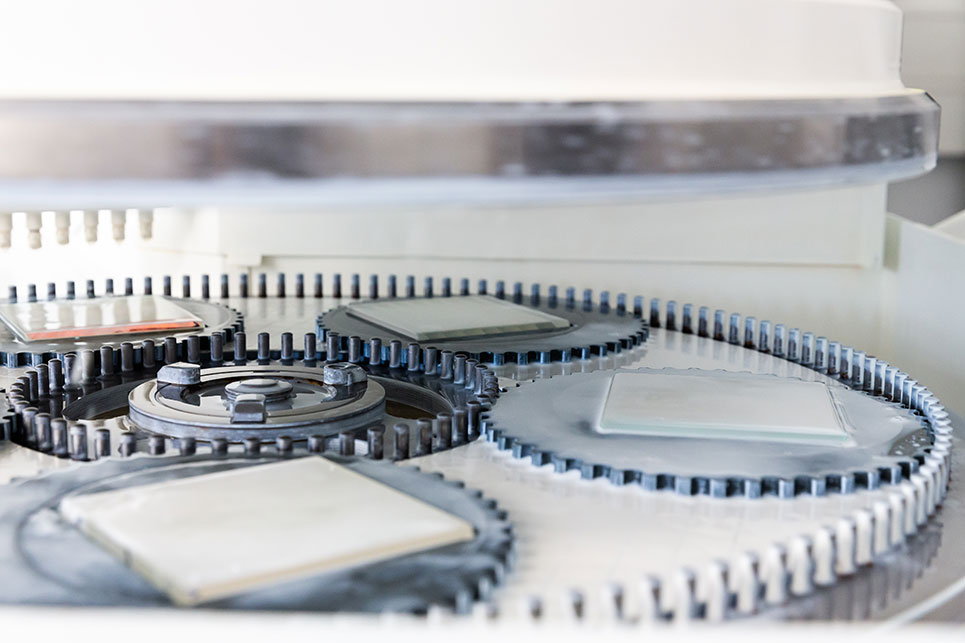

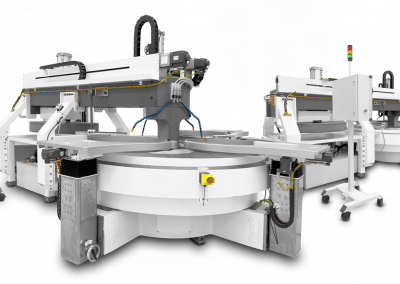

For all our grinding tools and processes as well as our polishing pads and solutions, we are able to supply customized dressing and conditioning tools.

Please contact us for your non-committal consultation.

Benefits of dressing tools for grinding tools:

- Maintains a long lifespan of the grinding tools as the binding is only removal marginally

- Easy to use

- No contamination with residues

- Very quick dressing – and shape correction cycles of usually just a few seconds

Benefits of PU pad dressing & conditioning tools:

- Extremely high lifespan

- No scratches from abrasive diamonds or break-offs

- Very cutting efficient and therefore ensures fast processing and easy shape correction

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.