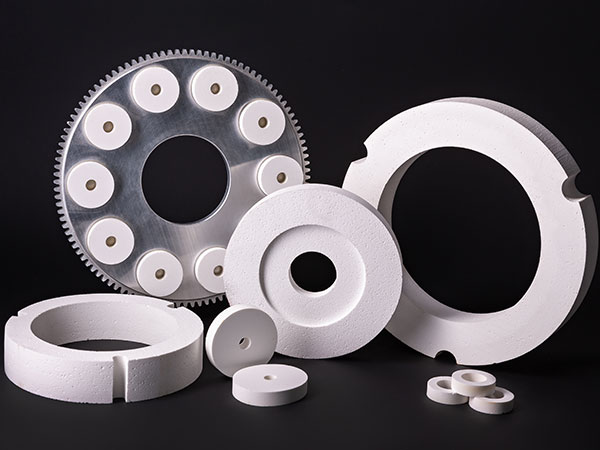

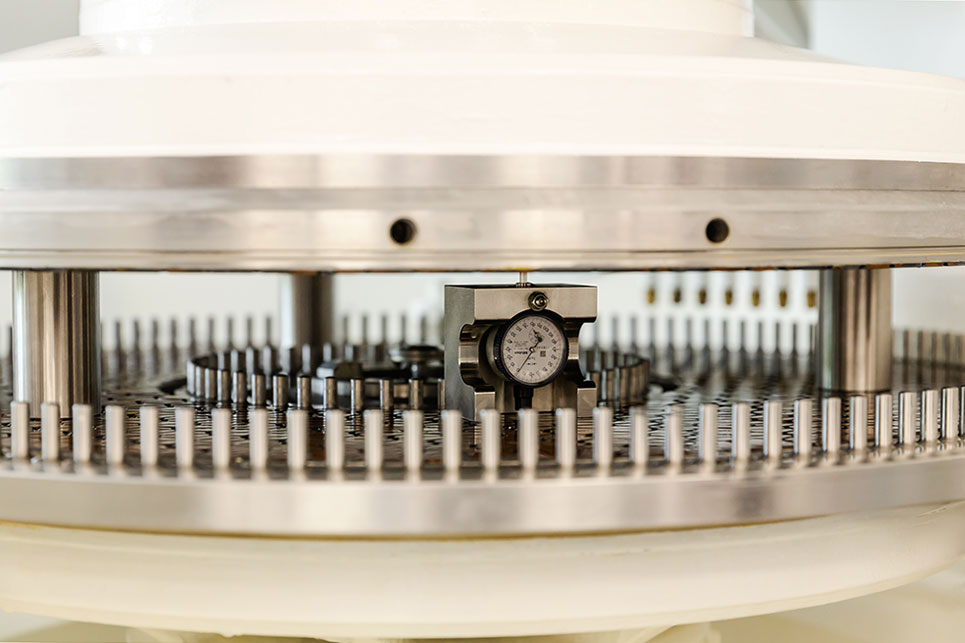

Polishing Pads

Home » Products » Consumables »

Polishing Pads

Polishing Pads

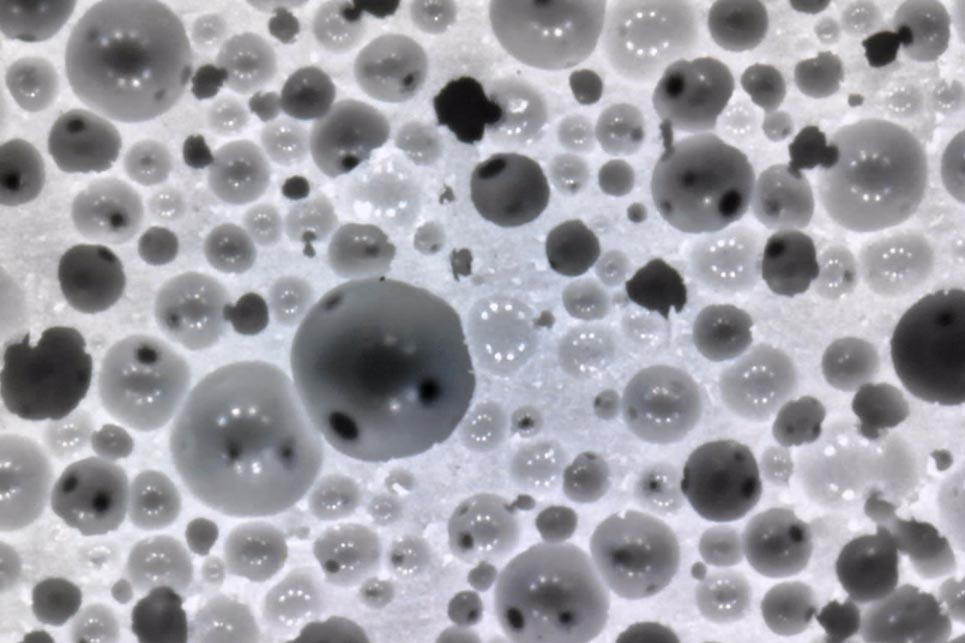

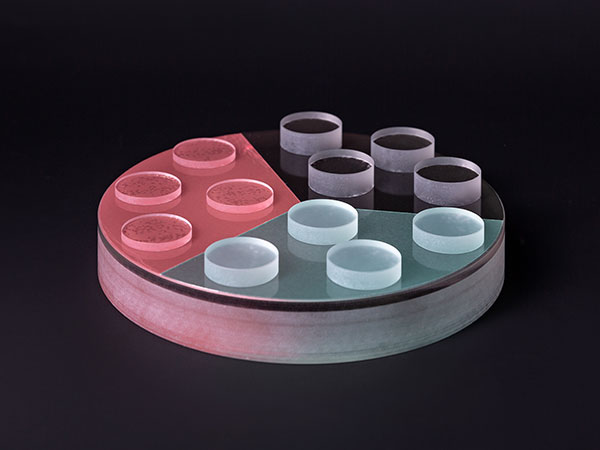

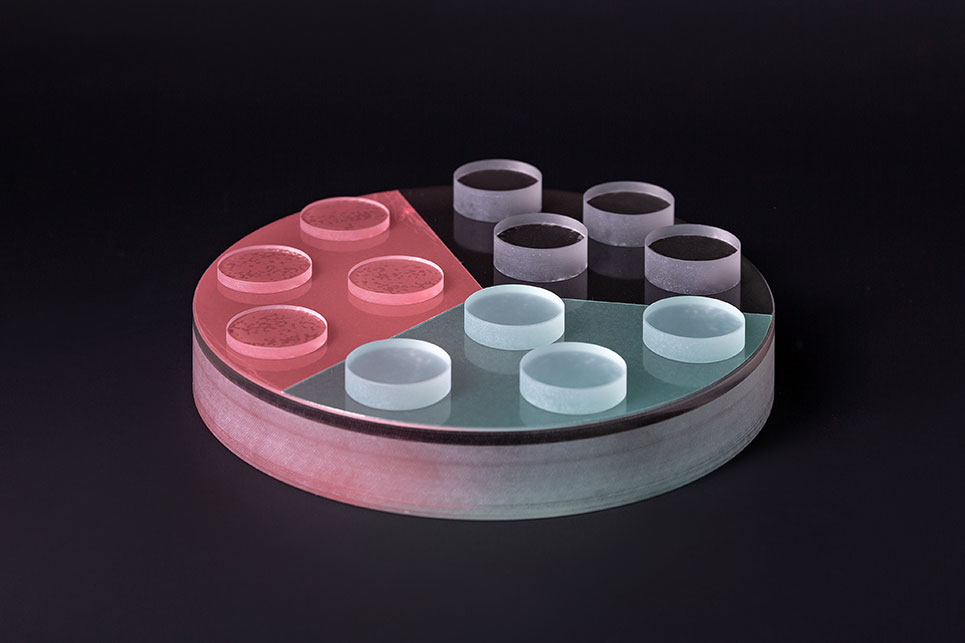

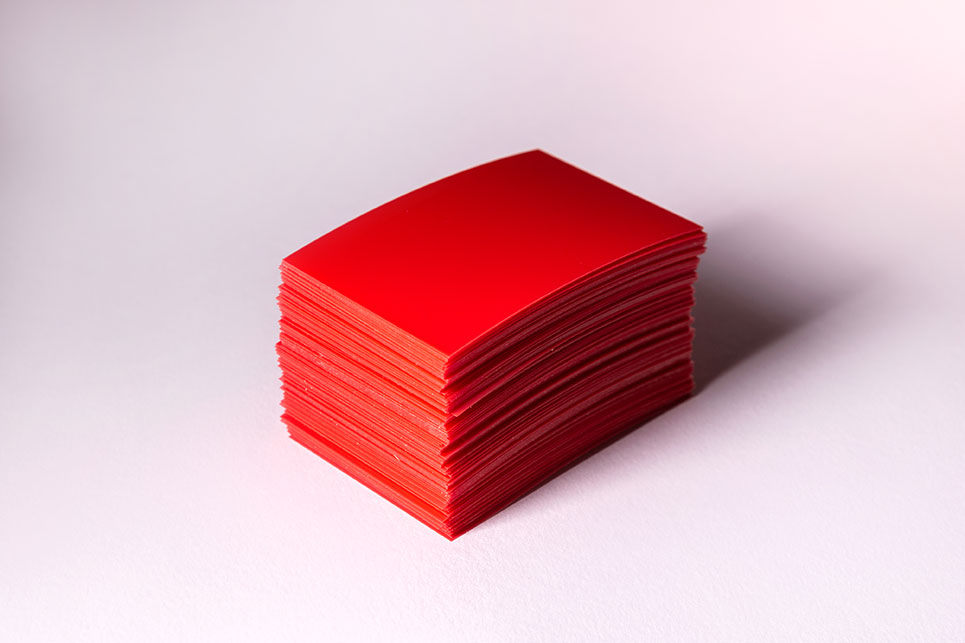

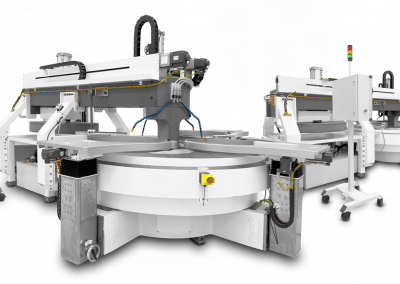

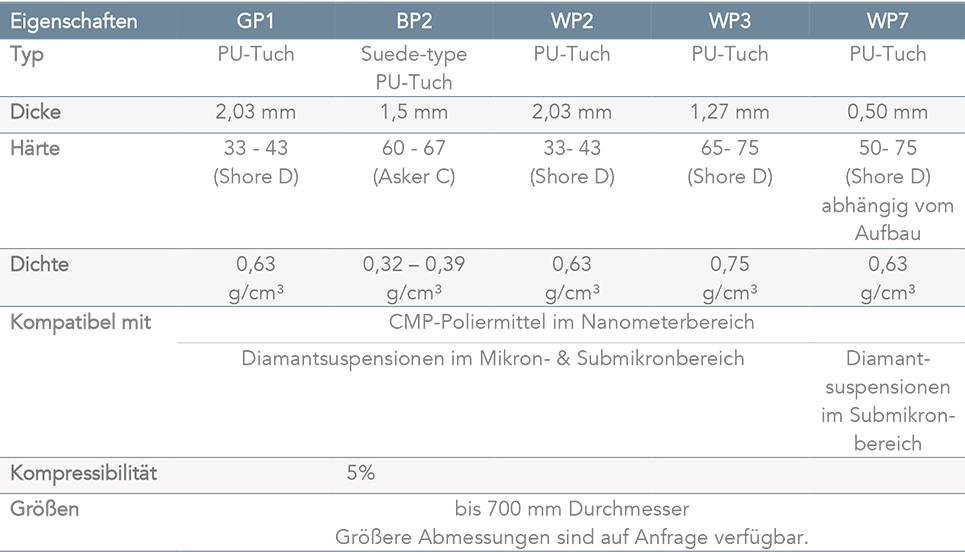

With dopa polishing pads you will achieve superior flatness, material removal rate (MRR) and surface quality on materials like glass, sapphire, silicon carbide and other ultra-hard carbides and nitrides.

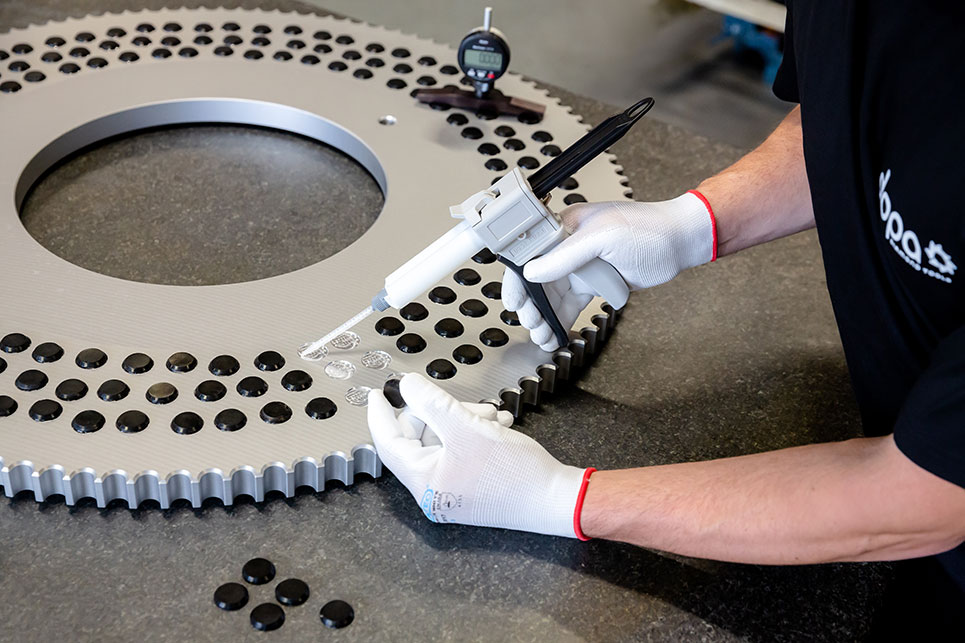

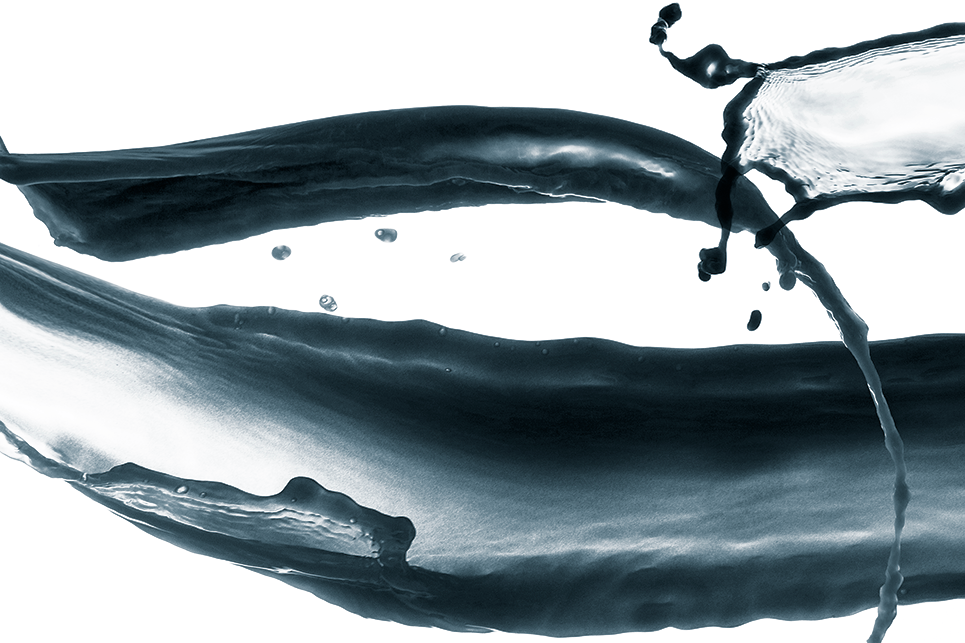

The dopa GP-1 works with Silica CMP slurries as well as with diamond slurries. You will achieve the best process results when using the pad in combination with dopa polishing slurries.

Customized grooving and slurry holes available upon request

Benefits of polishing pads

- Hohe Abtragsraten (MRR)

- Exzellente (mit GP1, WP2-7) bzw. gute (mit BP2) Ebenheit und TTV der bearbeiteten Komponenten

- Verbessert die Oberflächengüte und minimiert die Tiefenschädigung Ihrer Bauteile

- Erheblich verringerte Orangenhaut und Abrundung von Kanten

- Kompatibel mit Silizium-CMP-Suspensionen im Nanometerbereich und Diamantsuspensionen

- Gleichbleibende Abtragsraten, welche Ihnen eine bessere Prozesskontrolle ermöglichen

- Sehr beständiges Tuch mit langer Nutzungsdauer

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 58 58 428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Head of Sales Europe Tools and Machines

+49 (0)162 401 25 99

juergen.waidhas@dopa-diatools.com

Patrick Tresch

ASM for Tools & Machines

+41 (0)79 570 71 37

Matthew Pembroke

VP of Business Development North America

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 58 58 42 831

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.