WAMP Mounting Film

Home » Products » Consumables »

WAMP Mounting Film

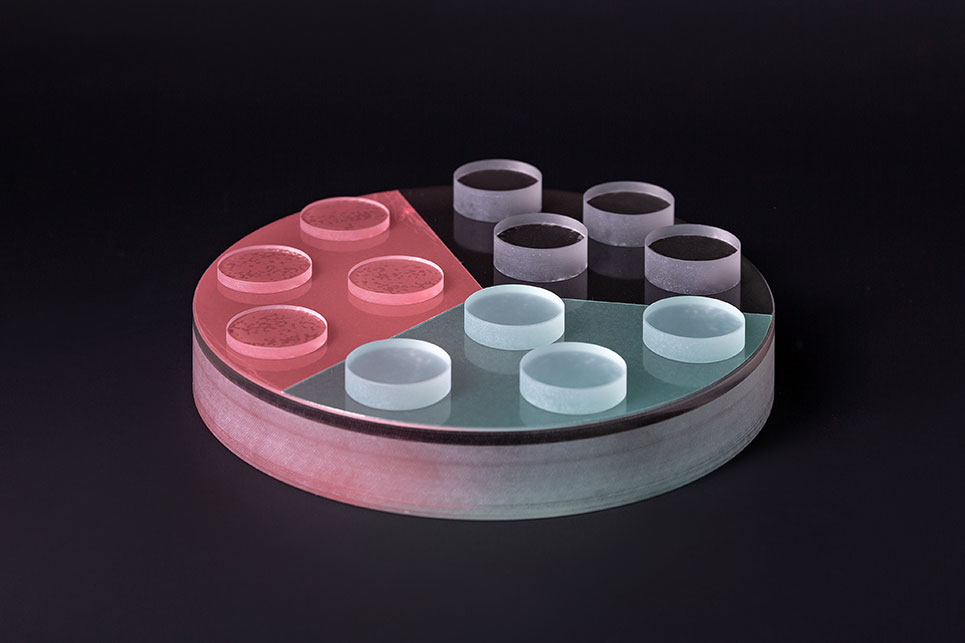

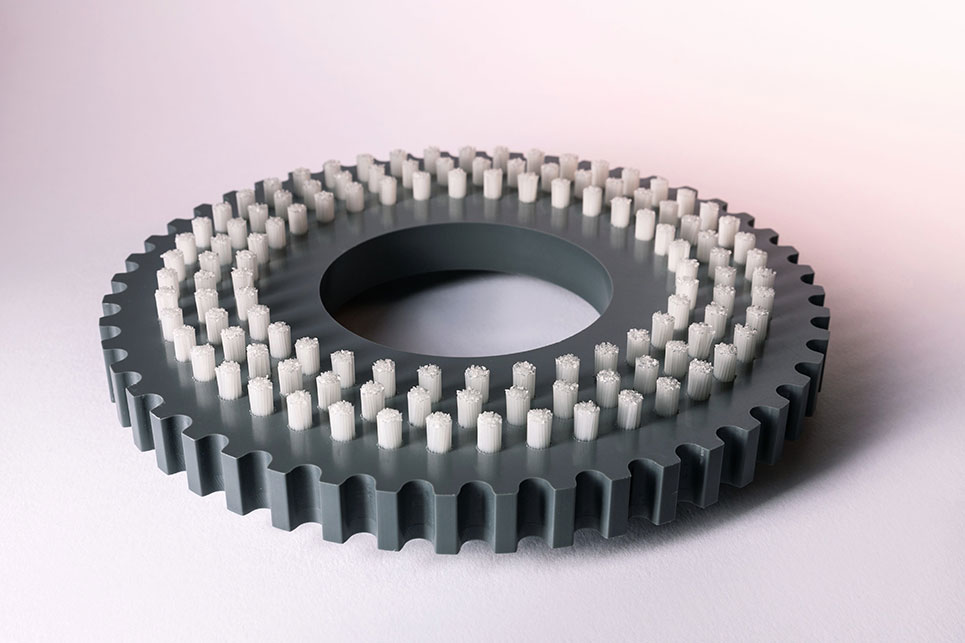

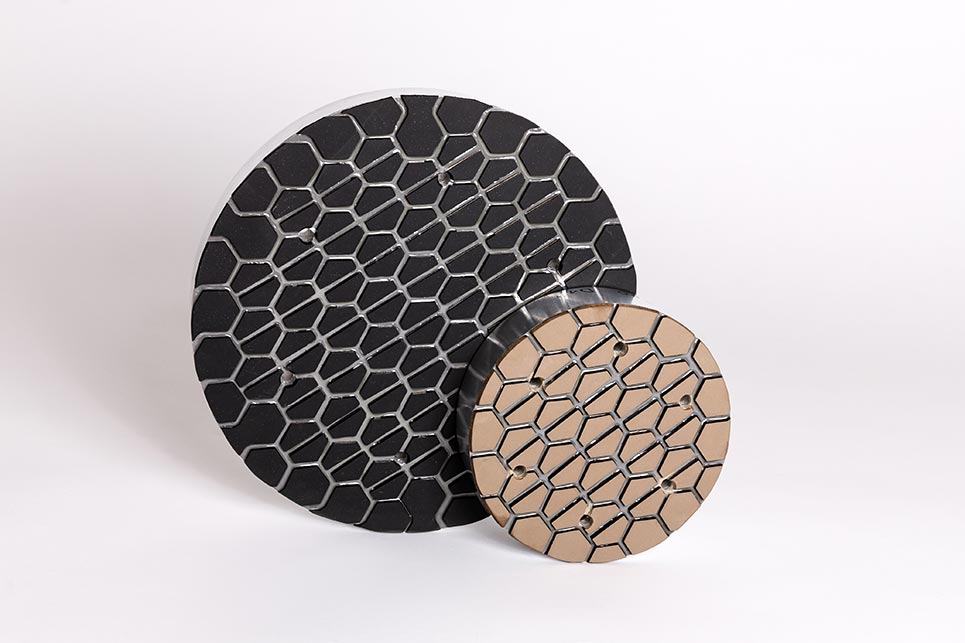

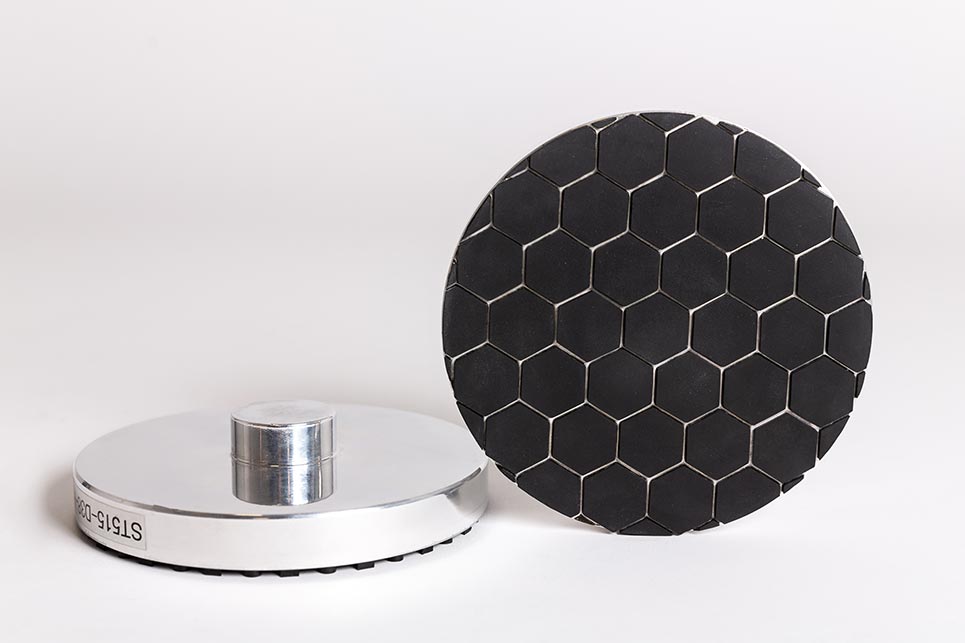

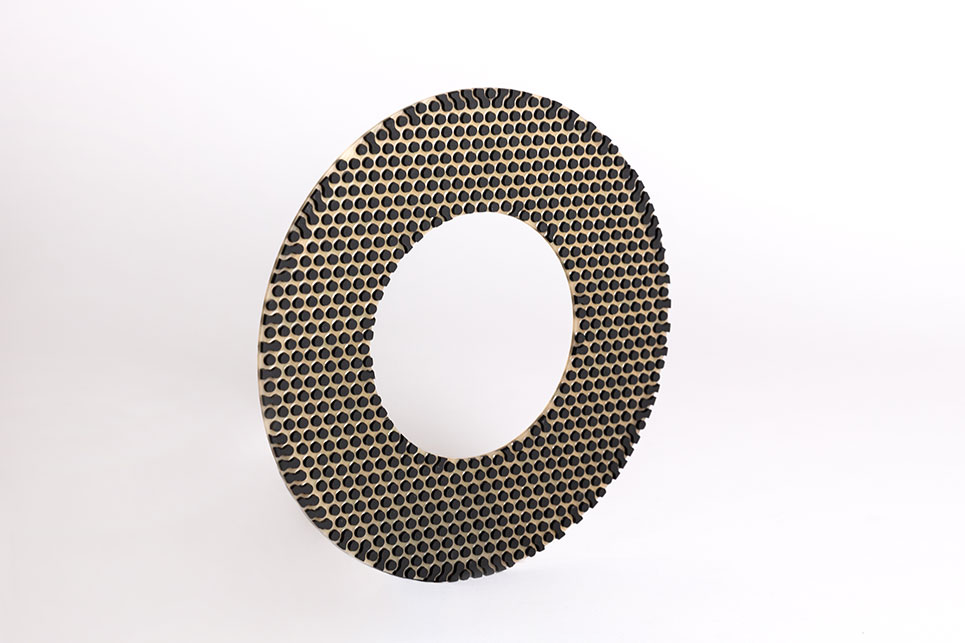

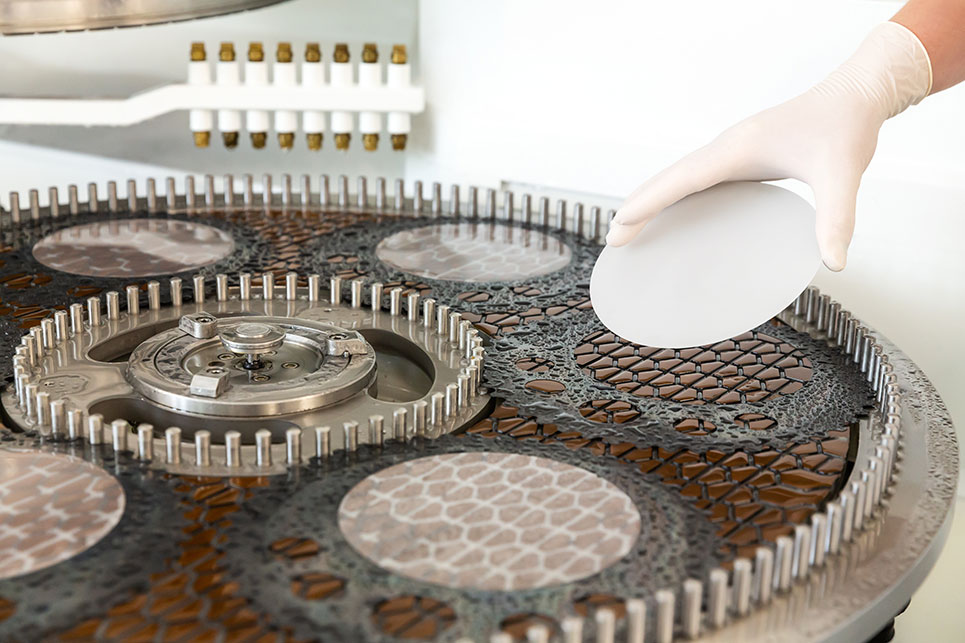

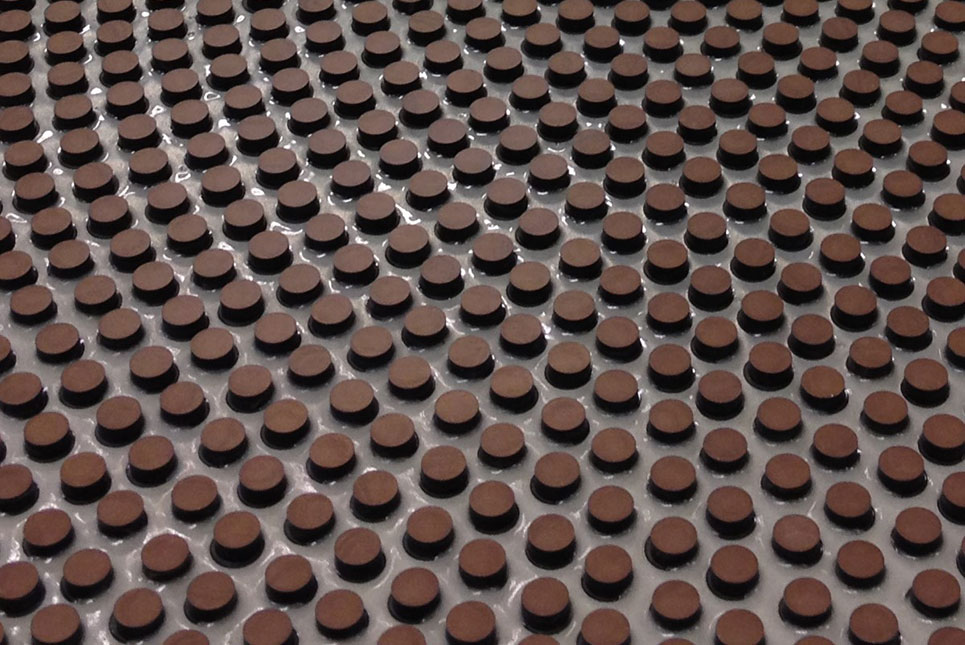

dopa WAMP mounting film is used to securely fix parts for single side grinding, lapping and

polishing processes on mounting plates. WAMP is a double-sided adhesive foil with a thickness tolerance of only about ± 1μm. Without preheating the base plate, it can be fast and easily applied and the components mounted.

Several glueing, cementing and optical contact bonding processes can be substituted with WAMP. It is compatible with glass, ceramic and metal base plates and nearly all types of substrates.

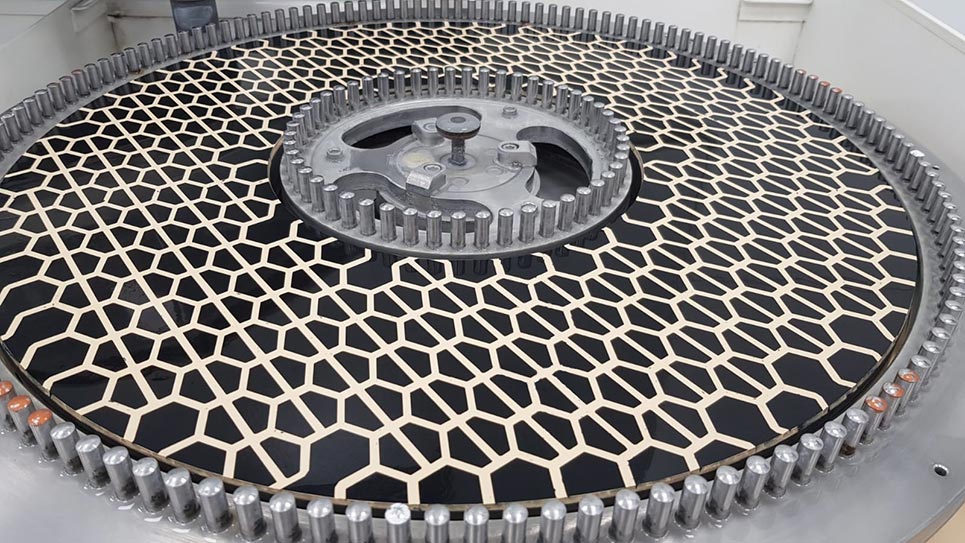

Thanks to the WAMP’s very high parallelism and homogeneity, you can produce very parallel parts, cut down the waxing error and have a stable process.

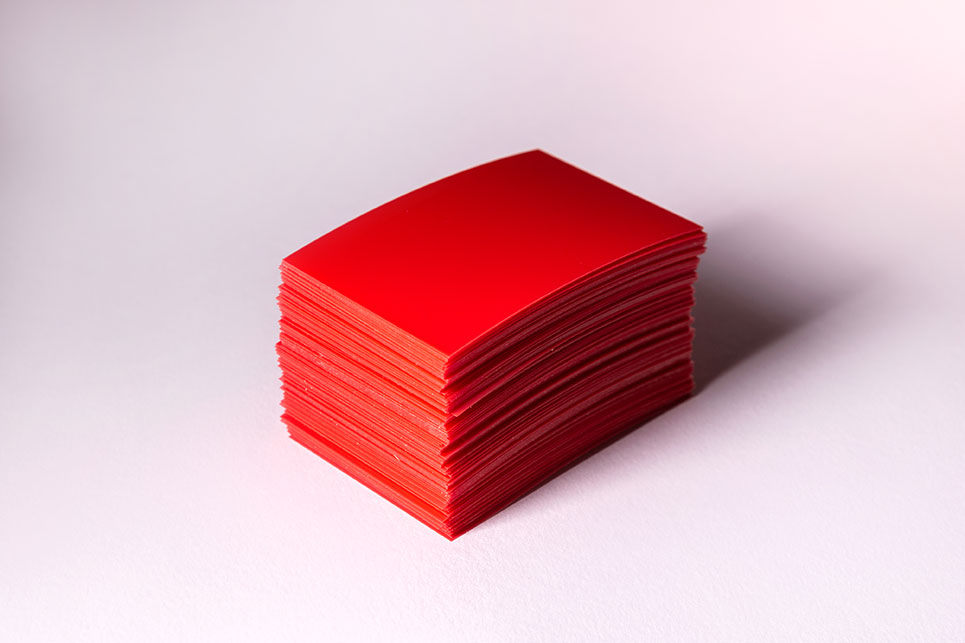

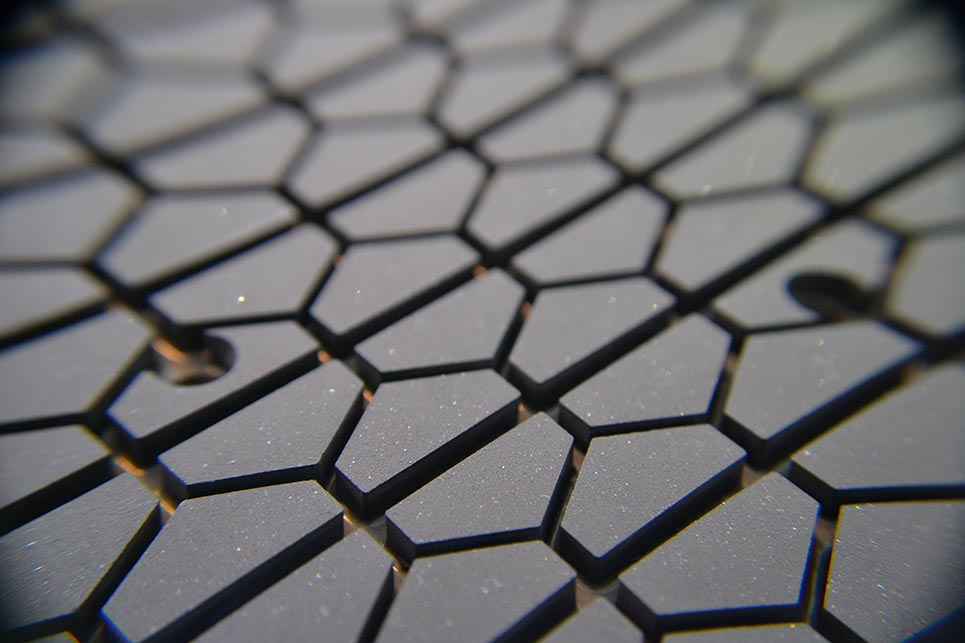

The WAMP mounting film has a thickness of about 0.246 mm (delivery state) and is made of 3 different layers:

| Layer | Description | Thickness |

|---|---|---|

| 1st Layer: | Protective film | 0.036 mm |

| 2nd Layer: | WAMP film | 0.174 mm |

| 3rd Layer: | Protective film | 0.036 mm |

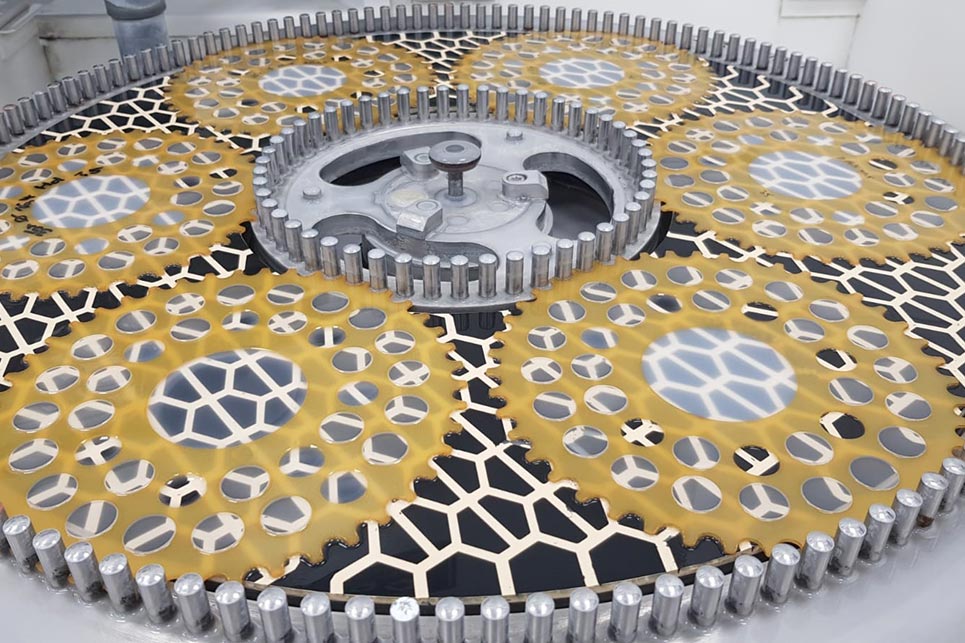

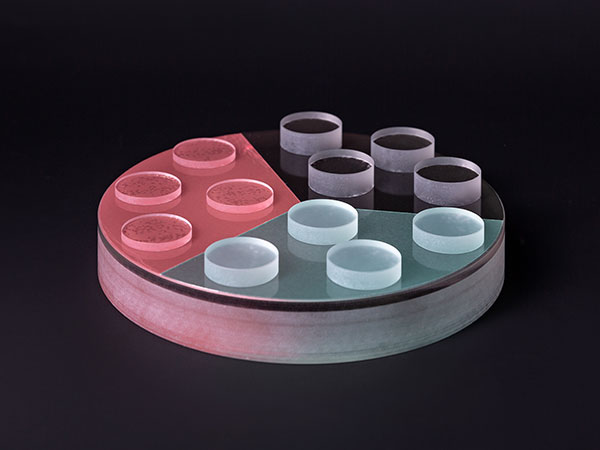

WAMP is available in 3 different color-coded release temperatures:

| Type | Release Temperature [°C] |

|---|---|

| Carbon-black WAMP | > 50 °C |

| Green WAMP | > 50 °C |

| Red WAMP | > 80 °C |

| Purple WAMP | > 100 °C |

You will find all necessary details how to use WAMP in our tutorial

PDF Download

Benefits of WAMP

- Easy and fast to apply

- Precise positioning

- No adhesive gaps or cementing failures

- Low release temperatures

- Fast and easy to remove without residues

→ Can be used to protected very delicate polished surfaces from scratching

→ No need for special cleaning - Low thickness tolerance

→ Can be used to process even very thin components (< 0.1 mm)

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.