Carriers

Home » Products » Consumables »

Carriers

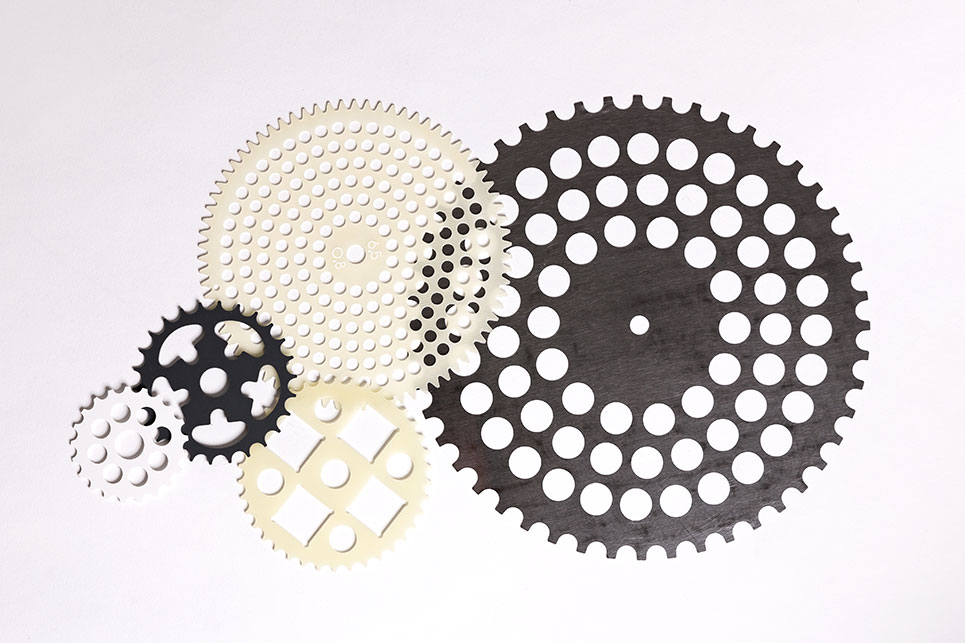

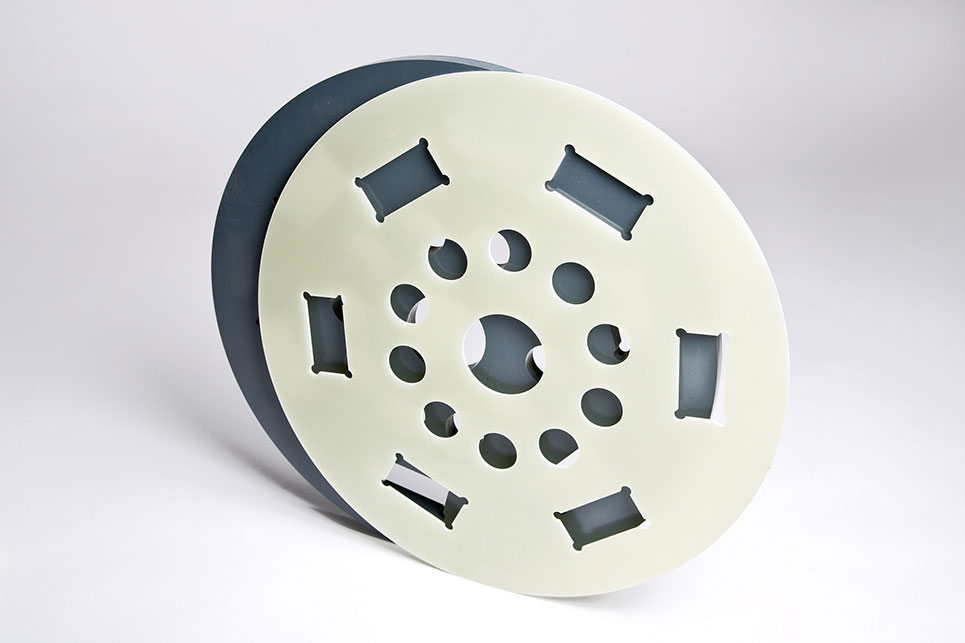

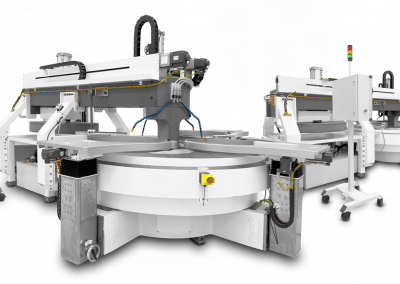

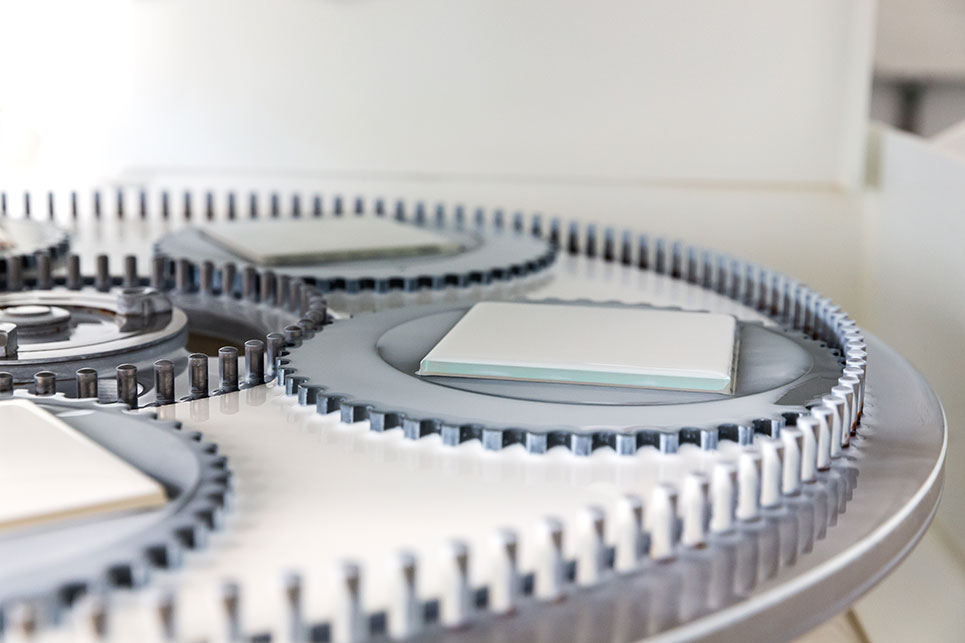

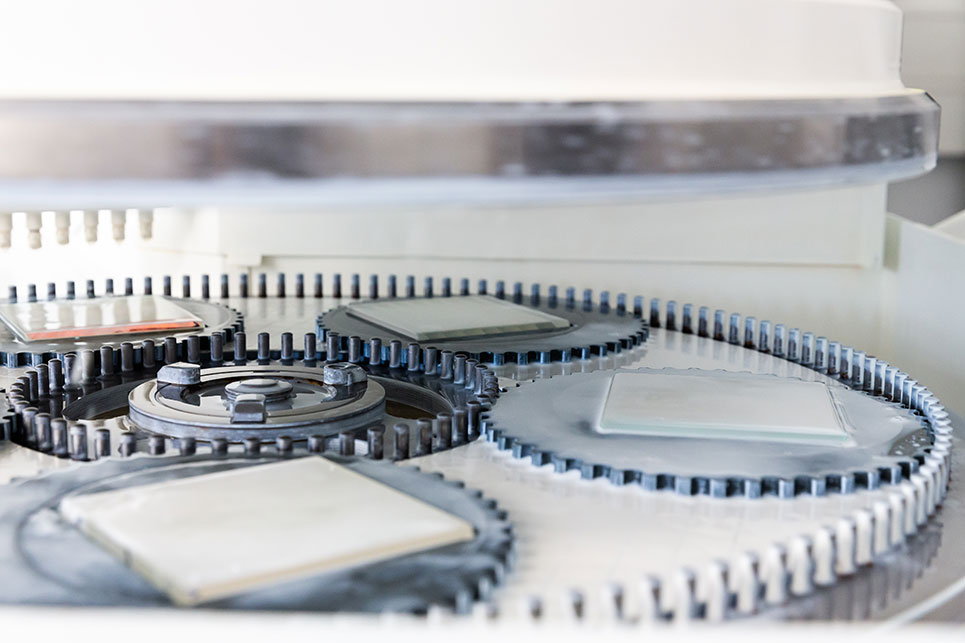

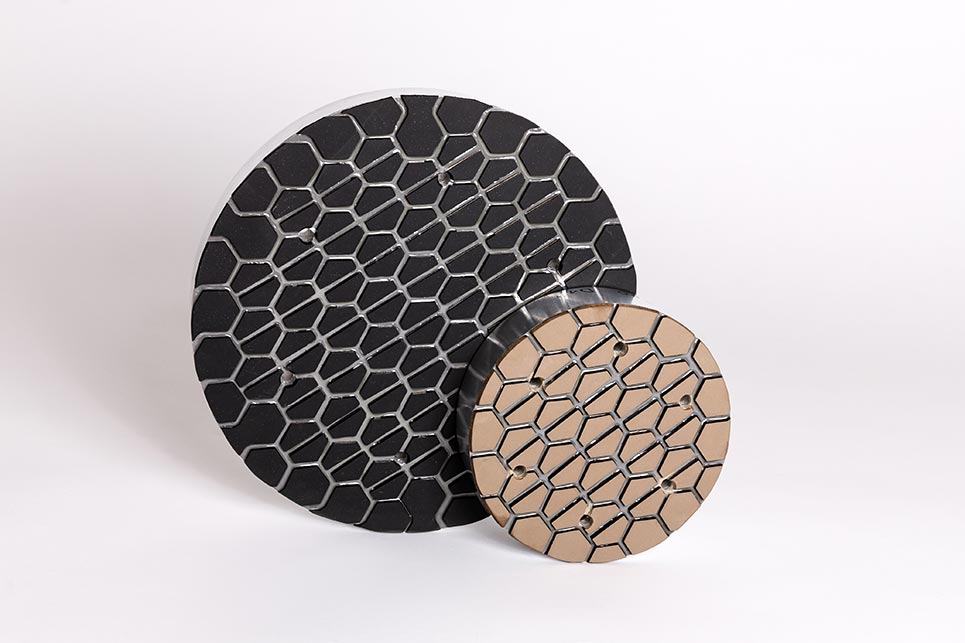

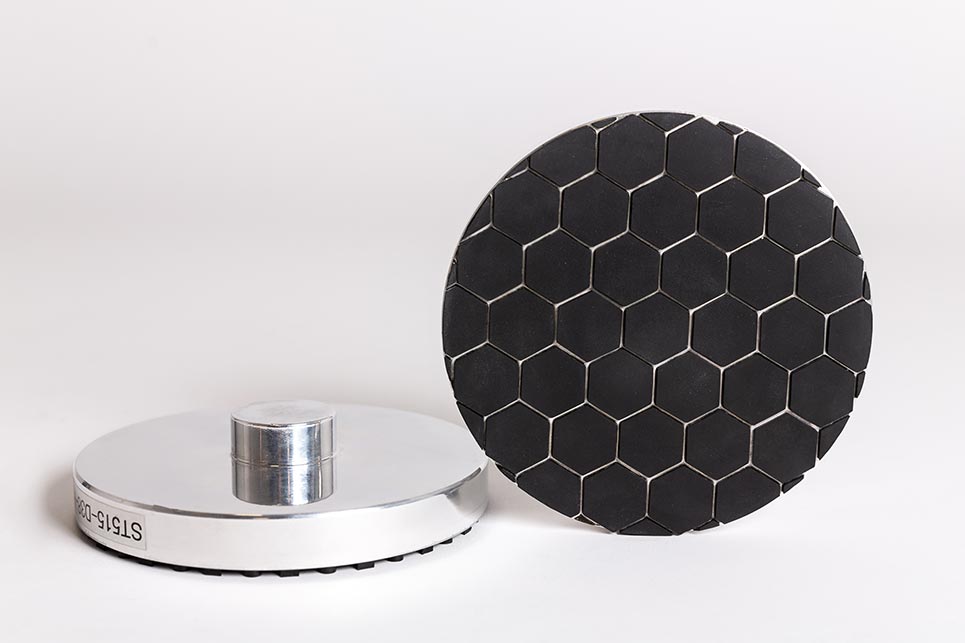

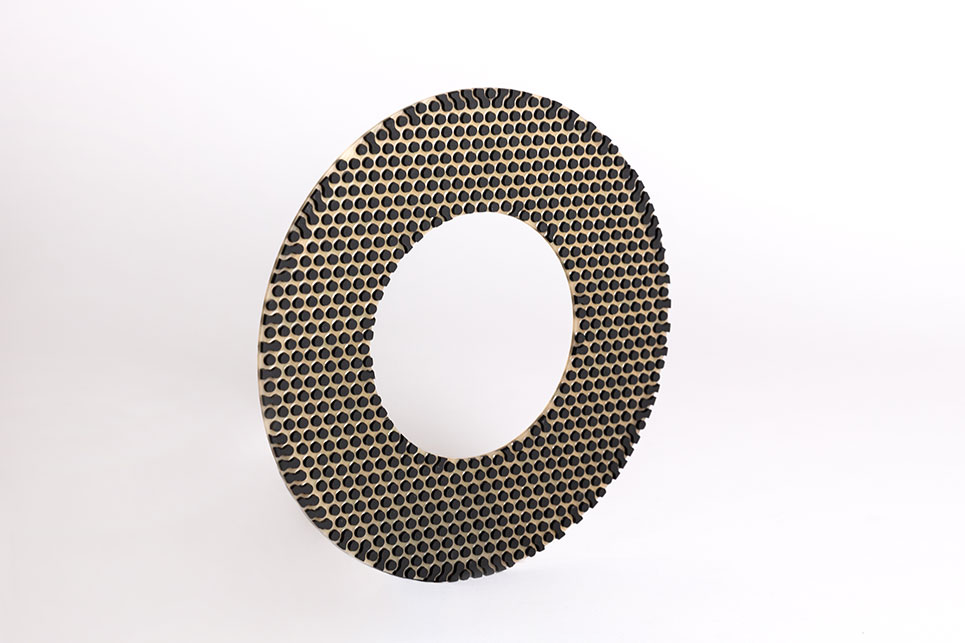

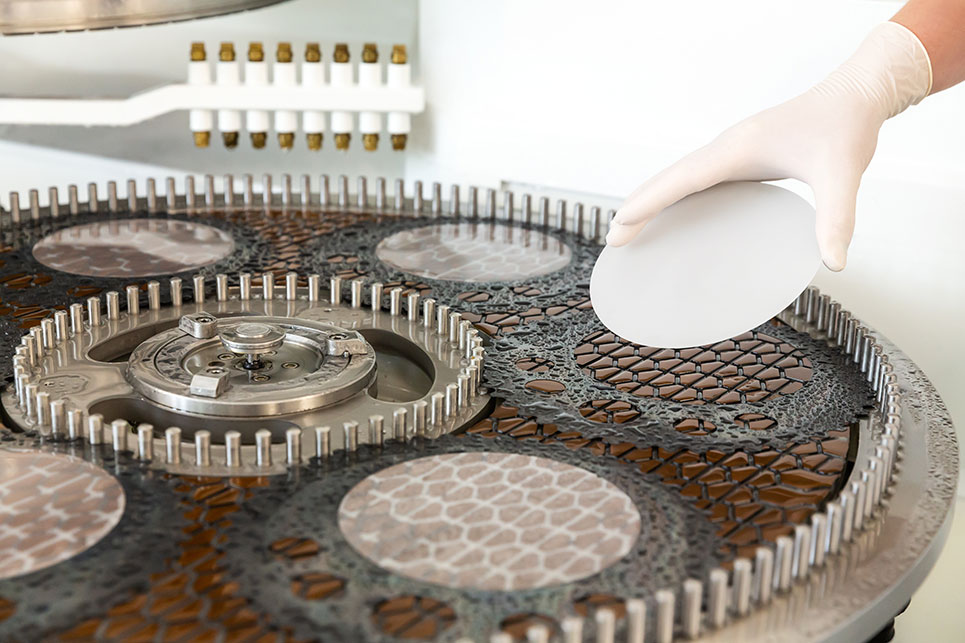

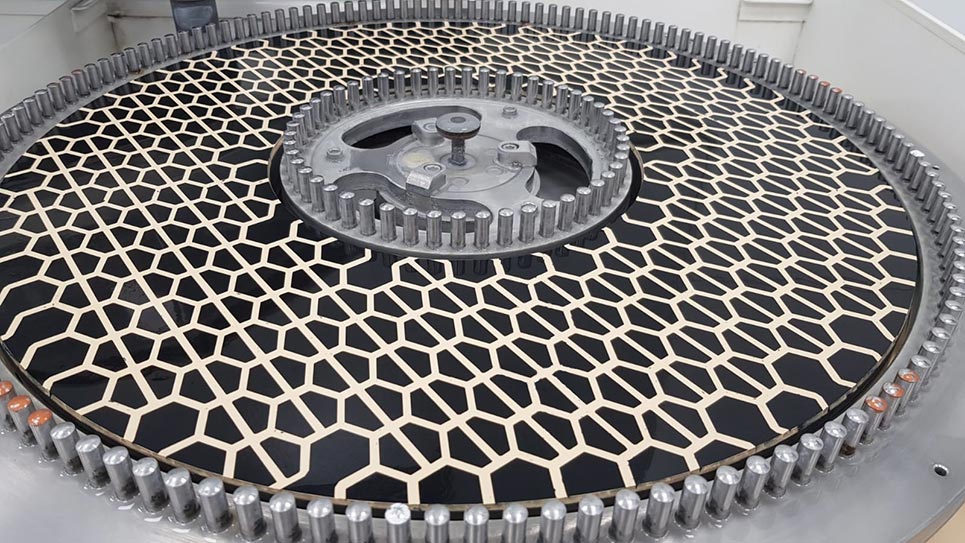

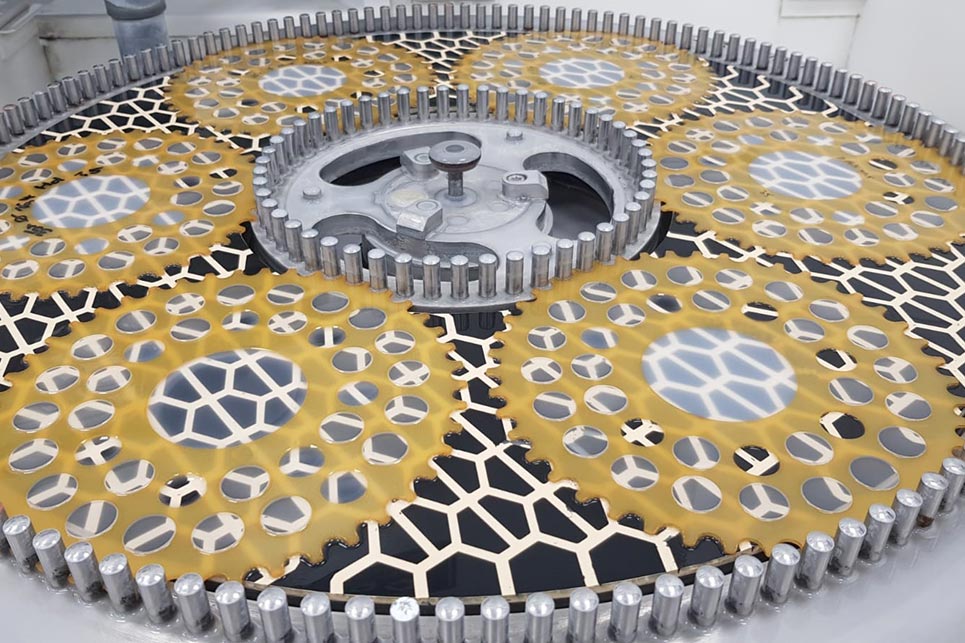

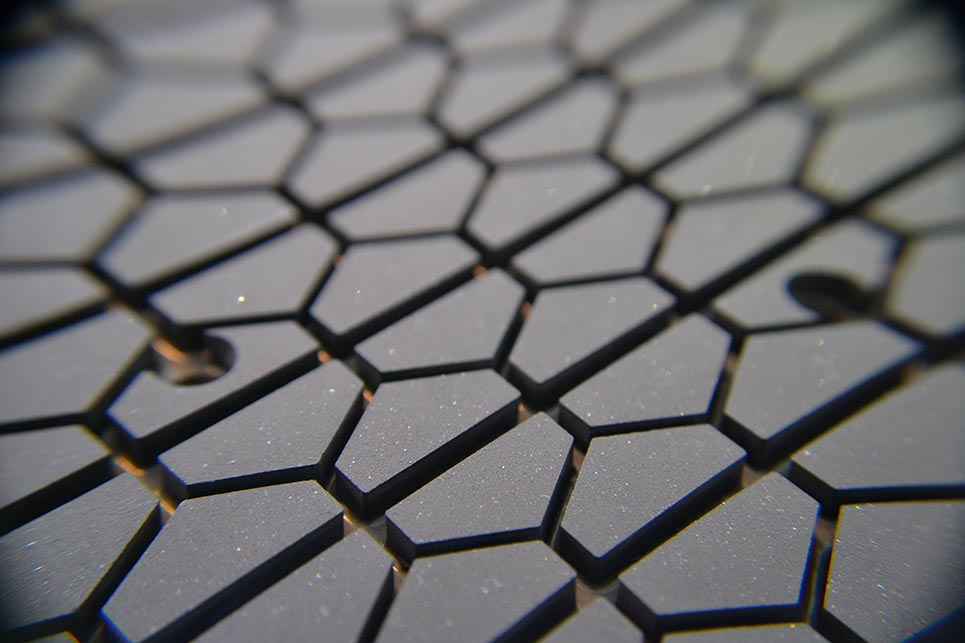

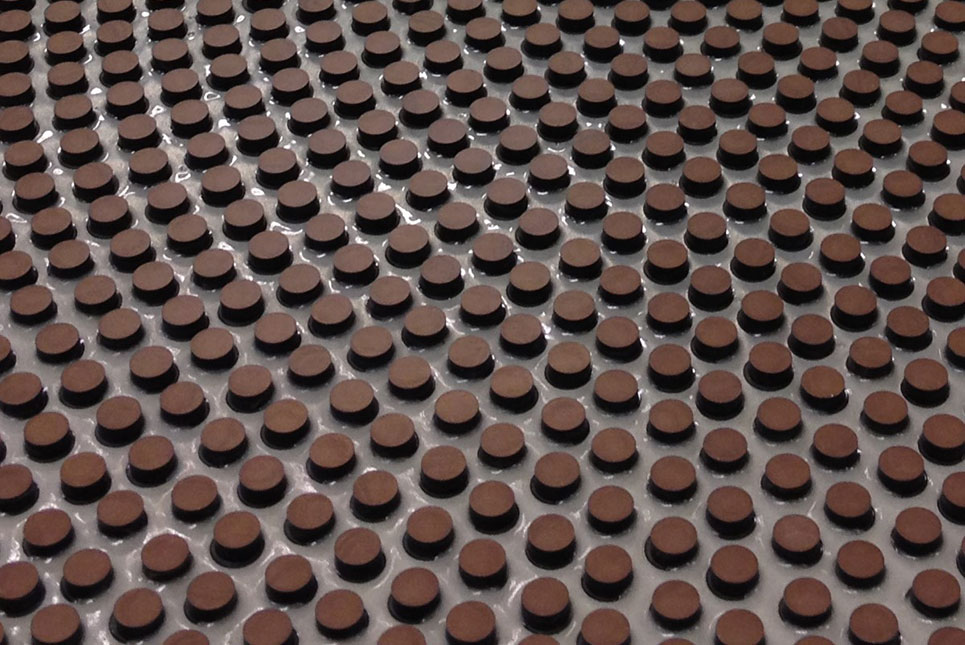

Carriers, Running Disks and Inlays

We are a producer of carriers, running disks and inlays for all single and double-sided lapping, grinding and polishing machines as for example: Carlap, Diskus, Engis, FLP Microfinishing, Fujikoshi, Hahn & Kolb, Hamai, Lapmaster, Leico, Melchiorre, Norton, Peter Wolters, PR-Hoffmann, Somos, Speedfam, Spitfire, Stähli, Stock, Strassbaugh, Supfina etc.

Shapes and dimensions we can do are hereby very flexible.

- Carrier thickness: starting from a thickness of 0.15 mm

- Carrier Dimension: up to 1500 mm

- Materials: GFK LAMITEX, Rigid PVC, Makrolon, Polyamid or spring steel

Additionally, we offer carriers in various specific materials. Carriers with other dimensions and thicknesses or very tight tolerances are also available upon request.

Customized Production

Whether you send us a complete CAD drawing (DXF or DWG file), a sketch or a sample – our design engineers handle your data fast and professionally.

Standard thicknesses on stock

In order to guarantee the shortest lead time, we always have for example LAMITEX, rigid PVC and spring steel in diverse thicknesses on stock:

Lamitex

| 0.5 mm | 1.8 mm | 6.0 mm |

| 0.7 mm | 2.0 mm | 8.0 mm |

| 1.0 mm | 2.5 mm | 10.0 mm |

| 1.2 mm | 3.0 mm | 12.0 mm |

| 1.5 mm | 4.0 mm | 15.0 mm |

| 1.7 mm | 5.0 mm | 20.0 mm |

Spring Steel

| 0.200 mm | 0.500 mm |

| 0.250 mm | 0.600 mm |

| 0.300 mm | 0.700 mm |

| 0.400 mm | 0.800 mm |

Rigid PVC

| 1.0 mm | 0.6 mm | 25.0 mm |

| 1.5 mm | 8.0 mm | 30.0 mm |

| 2.0 mm | 10.0 mm | 35.0 mm |

| 3.0 mm | 12.0 mm | 40.0 mm |

| 4.0 mm | 15.0 mm | 45.0 mm |

| 5.0 mm | 20.0 mm | 50.0 mm |

Other requirements

Should you need carriers in other thicknesses and with very tight tolerances, we can produce these according to your requirements.

PDF Download

PDF Download

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

If you have any questions or would like further information, please do not hesitate to contact us.