Grinding Wheels

Home » Products » Diamond Tools »

Grinding Wheels

Grinding Wheels

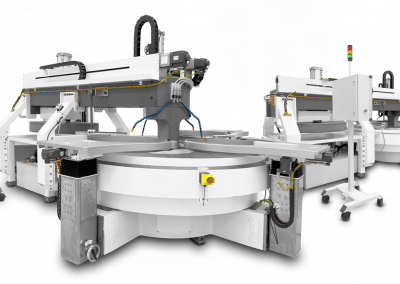

We develop and produce grinding wheels for all machine types and sizes – for single- as well as double-sided machines. Depending on your very needs, we will create the best grinding wheel to produce your components.

We gladly consult you:

- At processing very sensible materials such as calcium fluoride or germanium

- At grinding and polishing very hard materials such as sapphire, silicon carbide or spinell

- When it comes to producing very thin substrates

- At high requirements on flatness, parallelism, roughness or other specifications, that are important to you

- Already during feasibility studies or prototyping phase to create viable solutions

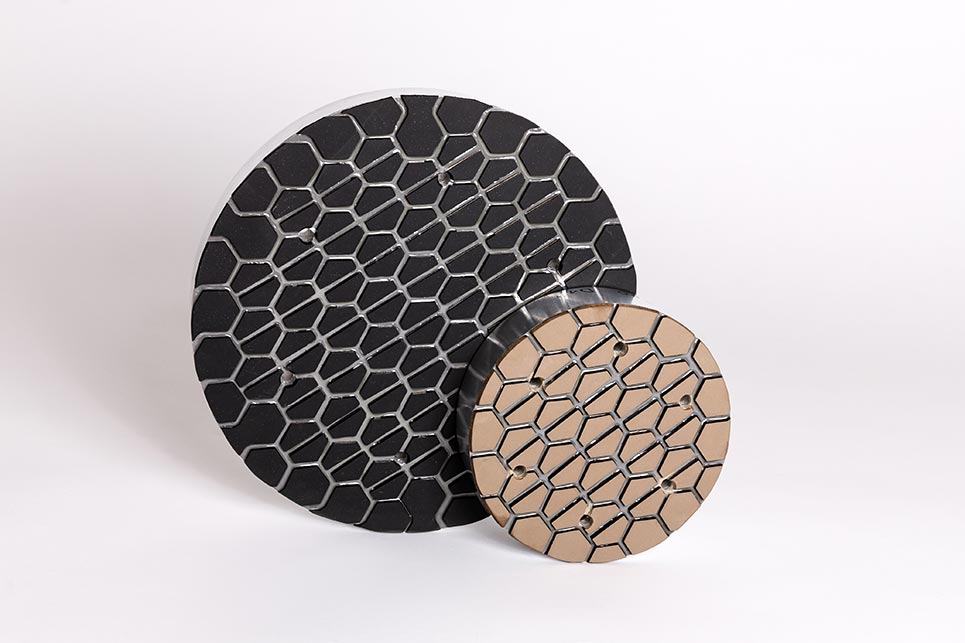

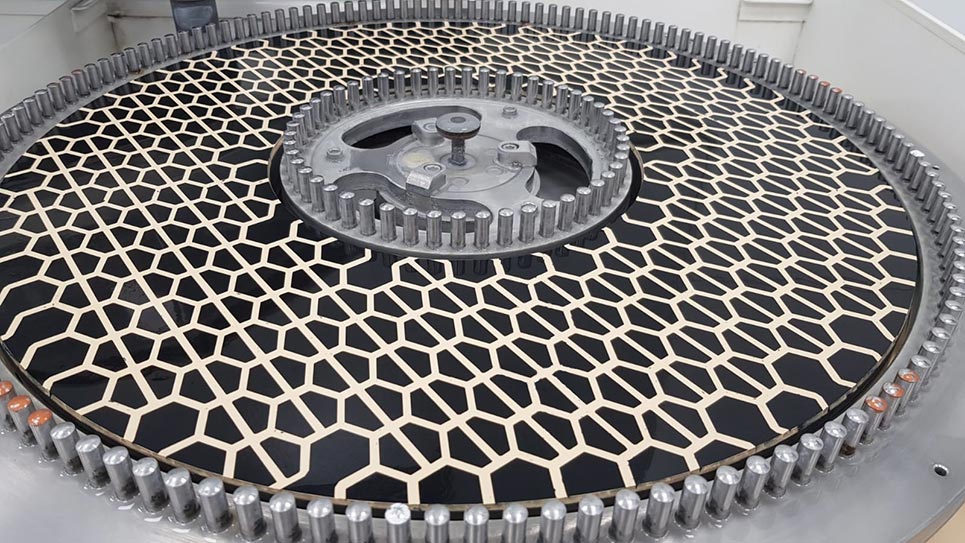

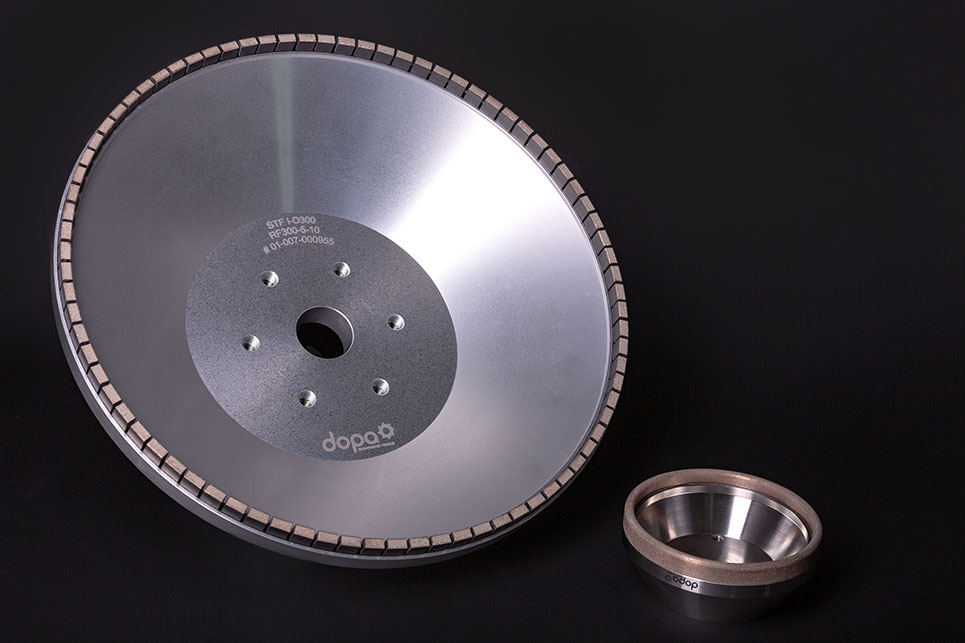

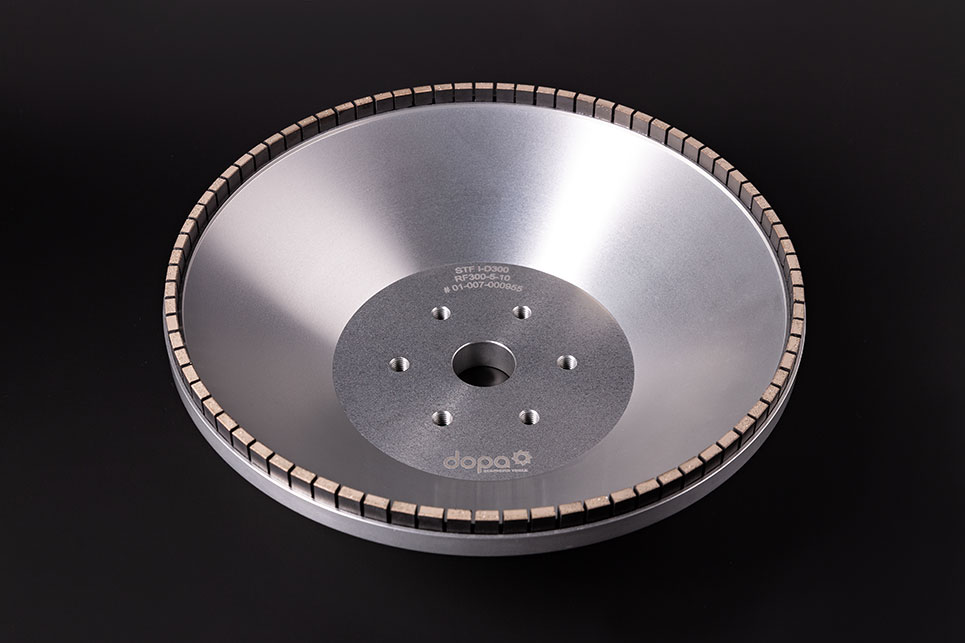

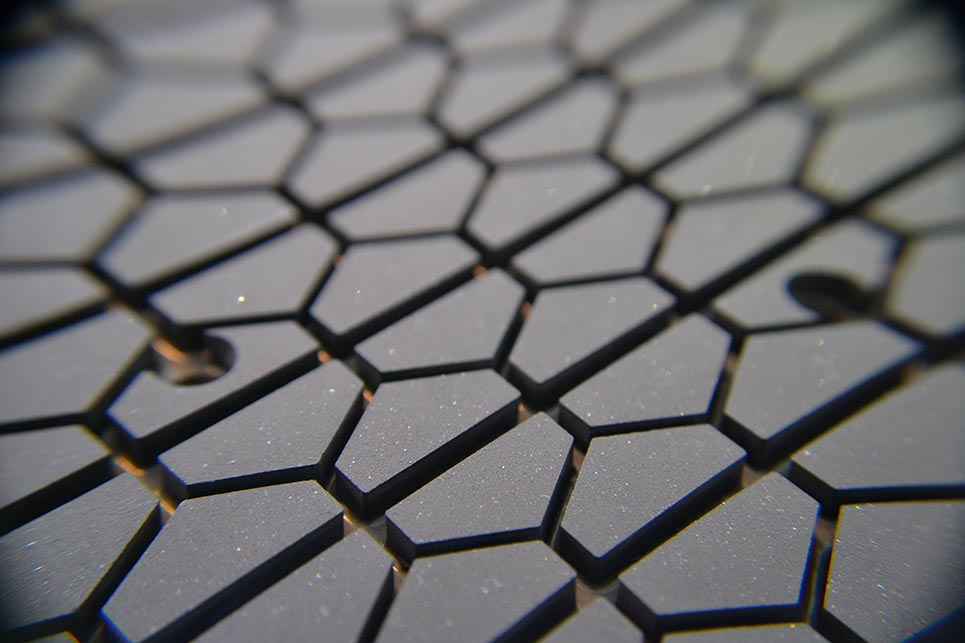

Segmented

Segmented grinding wheels are used for grinding very thin parts or a high density of components. The segmentation of the grinding wheel is above all to avoid tilting of the processed parts and to improve the edge sharpness.

The gap between the segments can be chosen flexibly and is usually determined by the size of the smallest components that need to be processed.

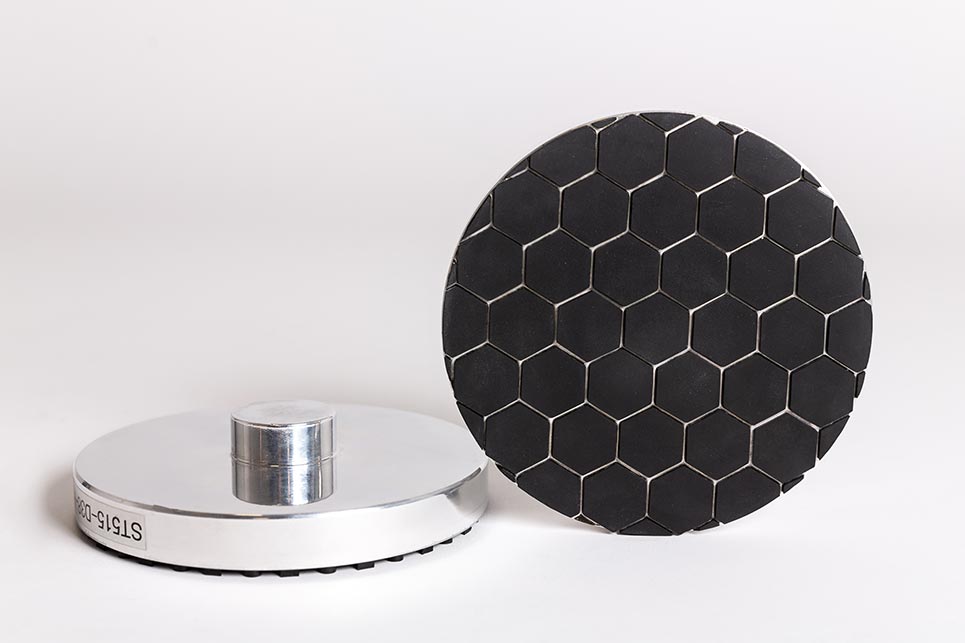

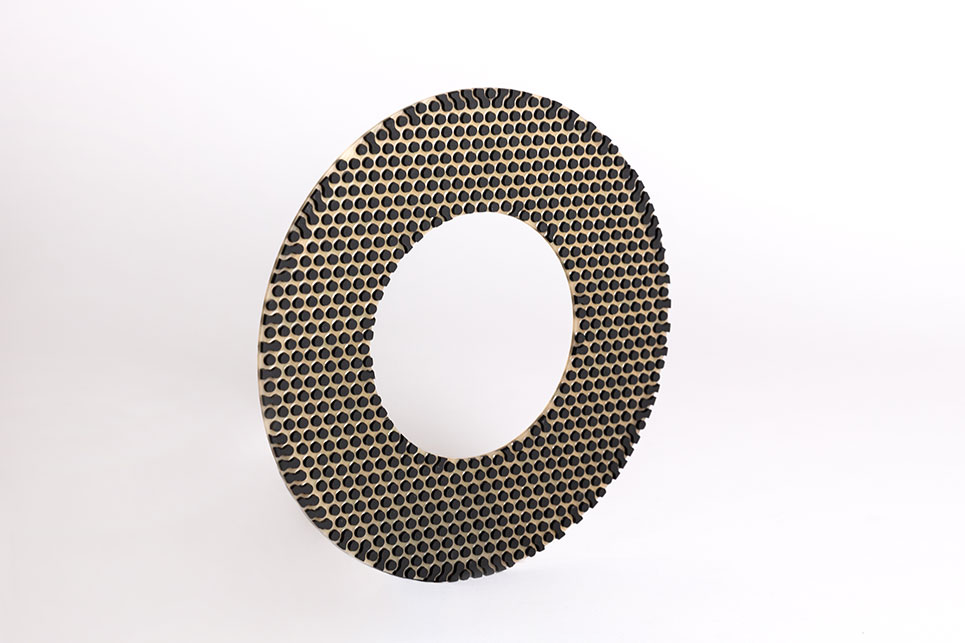

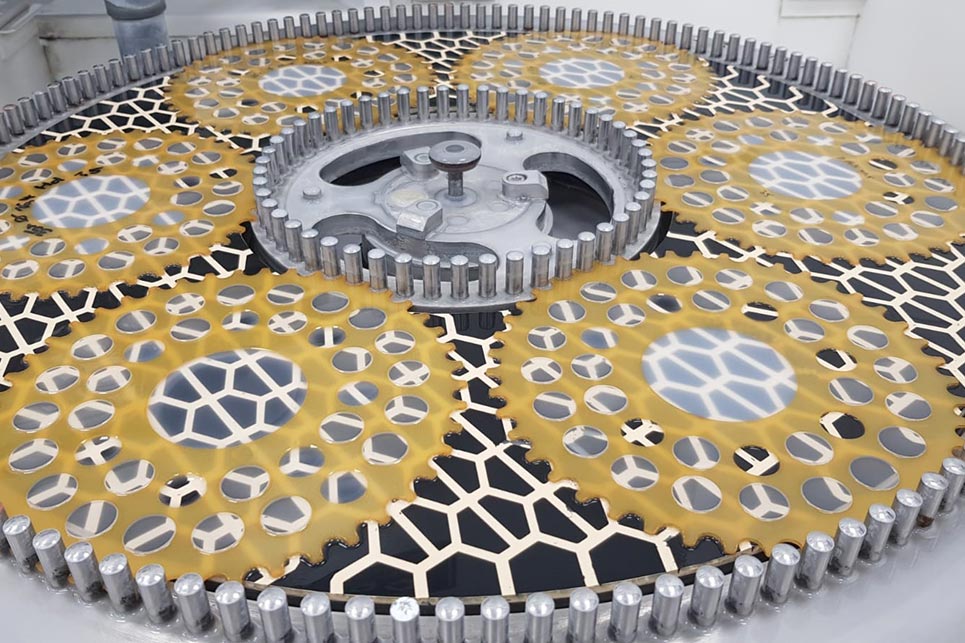

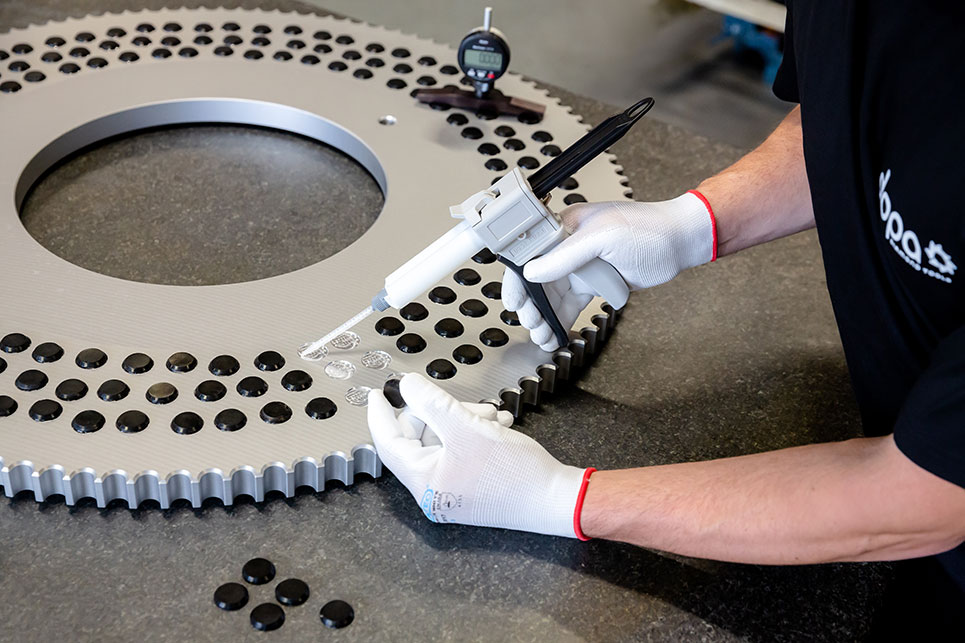

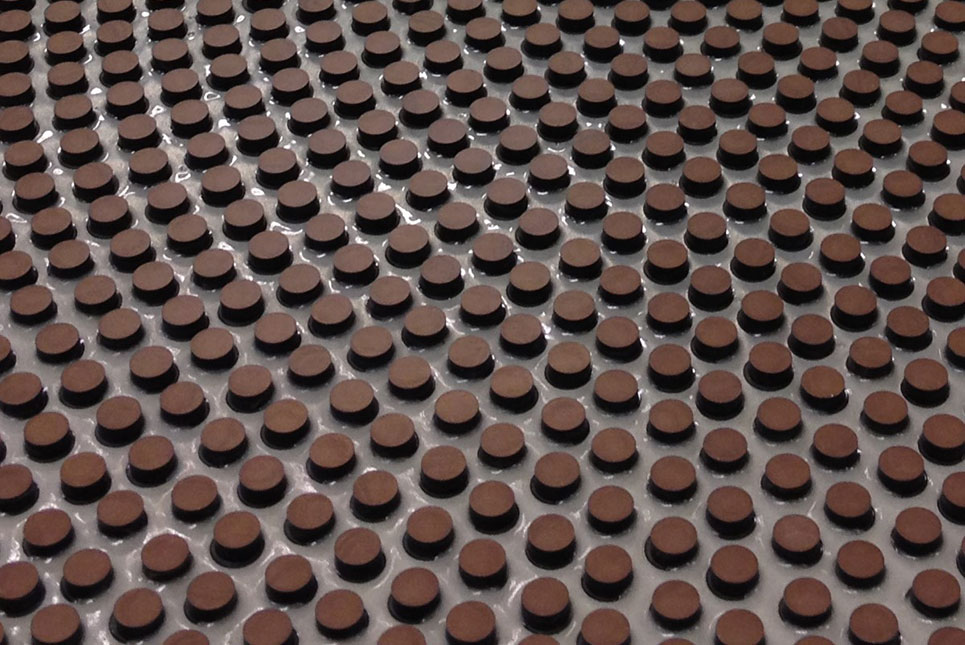

Pelleted

Pelleted grinding wheels are used where high removal rates combined with relatively low pressure are required.

These grinding wheels ensure a good removal of chipping and therefore avoid that clogging of the tools.

Grit size and pattern are completely flexible. We produce grinding wheels customized exactly to your production needs.

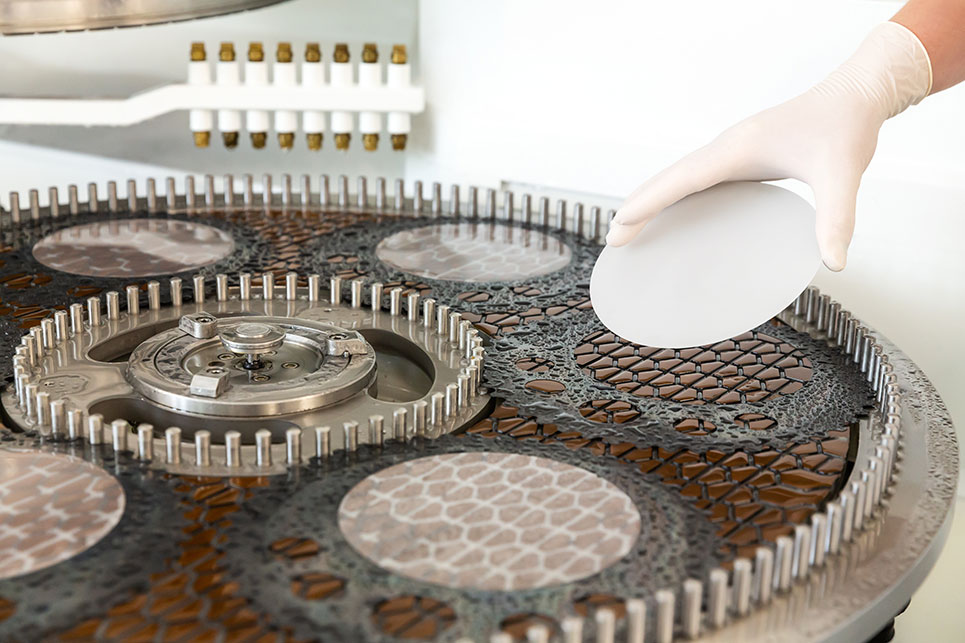

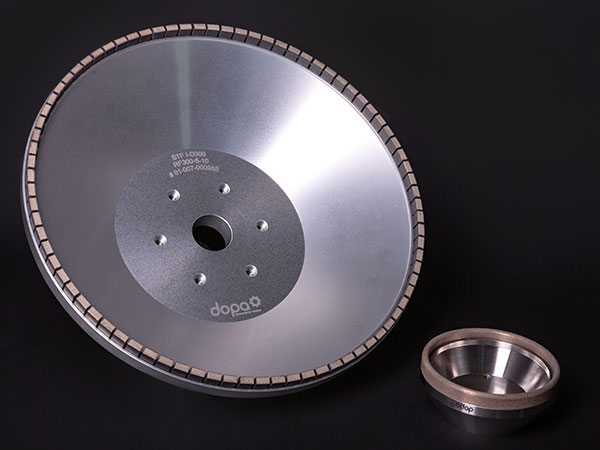

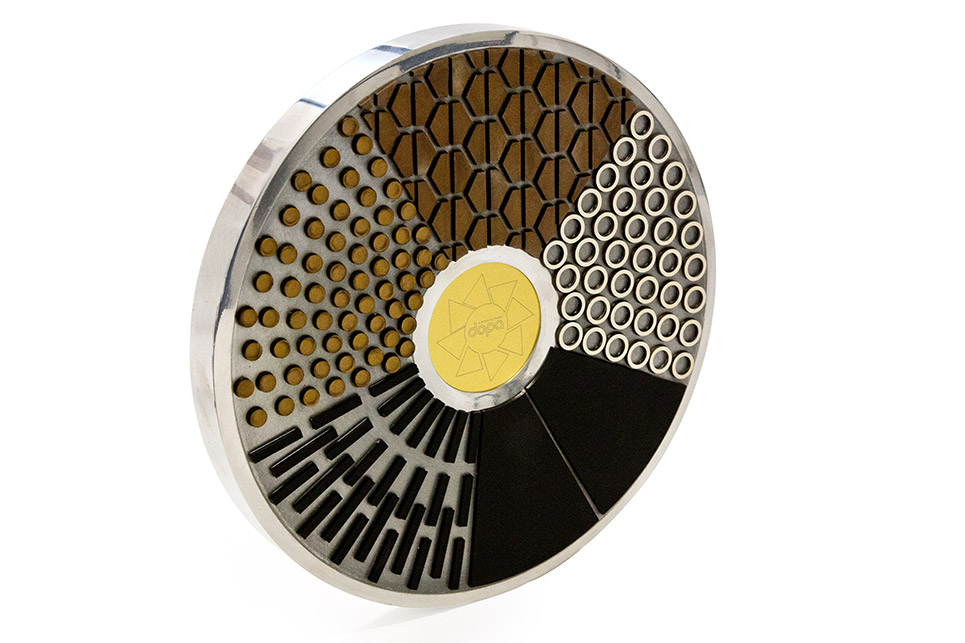

Fully Covered / Smoothed

Fully covered grinding wheels are typically used when many small items need to be processed at the same time. In the micro optics or watches industry, for example, several hundred components are ground simultaneously.

The full coverage ensures that all components are processed evenly on the grinding wheel. It avoids clipping or tilting of parts during the transition from one grinding segment to the next.

Subsequently, the edge quality of the components is improved and the risk of damage minimized, while the surface finish is significantly increased.

Olga Stark

Internal Sales for Tools, Machines & Consumables

+49 (0)30 5858428 32

olga.stark@dopa-diatools.com

Jürgen Waidhas

Sales Engineer for Tools, Machines & Consumables

+49 (0)1624012599

juergen.waidhas@dopa-diatools.com

Mario Patraschkov

Head of Sales Tools, Machines & Consumables

+49 (0)30 5858428 31

mario@dopa-diatools.com

Please contact us for further information.

We would be pleased to assist you with our expertise in selecting and customizing the tools to your needs!